Alfalfa Dryer used in Pelletizing

| Condition:New | Type:Rotary Drying Equipment | Place of Origin:Shandong China (Mainland) | Brand Name:Changsheng |

| Model Number:DH600*6000 | Voltage:380V,50Hz,3phases | Power(W):3kW | Dimension(L*W*H):1.69 |

| Weight:2900kg | Certification:CE&ISO9001 | Warranty:one year | After-sales Service Provided:Overseas third-party support available |

| capacity:500-3000kg/h |

Alfalfa Dryer used in Pelletizing

Shandong Changsheng Construction Machine Co.Ltd has devoted to research and produce pellet production line machines for biomass fuel pellets, animal feed pellets and organic fertilizer pellets, including all kinds of pellets machines, hammer mill, wood crusher, dryerand other related equipment.

It depends on your process…Pelletizing requires drying

Advantages ofdryer

•Greatest capacity

•Lowest electrical power

•Minimal steelwork for erection

•Good energy efficiency: 1,500 (w/ FGR) to 1,800 Btu/lb evaporation

•Feed size flexibility and can accept hottest flue gases

•Low O&M costs

The Description of Alfalfa Dryer used in Pelletizing

1,Alfalfa Dryer used in Pelletizing is to dry some powder and big output materials with high humidity, such as cement, wood chips, sawdust, stalk, straw, grass, animal feed,ect.

2,Alfalfa Dryer used in Pelletizing is mainly for drying the small diameter raw material less than 7mm, The moisture content less than 65%.

3,Alfalfa Dryer used in Pelletizing adopts time lays low-speed rotarying, curved plate hammering, dispersing raw materials with high moisture evaporative. Capacity is 0.5-3.0ton per hour.

4,Alfalfa Dryer used in Pelletizing is more convenient and efficient to dry. Now, it has been widely used in personal and general industry.

Alfalfa Dryer used in Pelletizing work processing:

1, Firstly, Theraw materials enter into the drying sysem by conveyor or bucket conveyor, the alfalfa sawdust raised by lifting plate to making alfalfa sawdust and heat totally contact with each other.

2, The wood sawdust are evenly distributed in the cylinder,at the start ofAlfalfa Dryer used in Pelletizing and the end of the dryer have temperature detector, so you can check everywhere temperature inside the Alfalfa Dryer used in Pelletizing.

3, AfterAlfalfa Dryer used in Pelletizing have fan, it will absorb the hot air into the dryer and finally make the material to dry.

4, Between Alfalfa Dryer used in Pelletizing and fan have cyclone, it can collect the dust out from the dryer.

Rotary dryer construction

Technical parameter of Rotary Dryer used in Pelletizing

| Model | Rotary drum | Rotary speed (r/min) | Power (kW) | Volume (m³) | Output capacity (t/h) | Net Weight (kg) | |

| Diameter (mm) | Length (m) | ||||||

| THG6 | 600 | 6.0 | 3-8 | 3 | 1.69 | 0.5-1.5 | 2.9 |

| THG8 | 800 | 8.0 | 3-8 | 4 | 4.01 | 0.8-2.0 | 3.5 |

| THG8 | 800 | 10.0 | 3-8 | 4 | 5.02 | 0.8-2.5 | 4.5 |

| THG10 | 1000 | 10.0 | 3-8 | 5.5 | 7.85 | 1.0-3.5 | 5.6 |

| THG12 | 1200 | 10.0 | 3-8 | 7.5 | 11.3 | 1.8-5 | 14.5 |

| THG12 | 1200 | 12.0 | 3-8 | 11 | 13.56 | 2.0-6.0 | 14.8 |

| THG15 | 1500 | 12.0 | 2-6 | 15 | 21.19 | 3.5-9.0 | 17.8 |

| THG18 | 1800 | 12.0 | 2-6 | 18 | 30.52 | 5.0-12.0 | 25 |

| THG22 | 2200 | 12.0 | 1.5-6 | 18.5 | 45.59 | 6.0-15.0 | 33 |

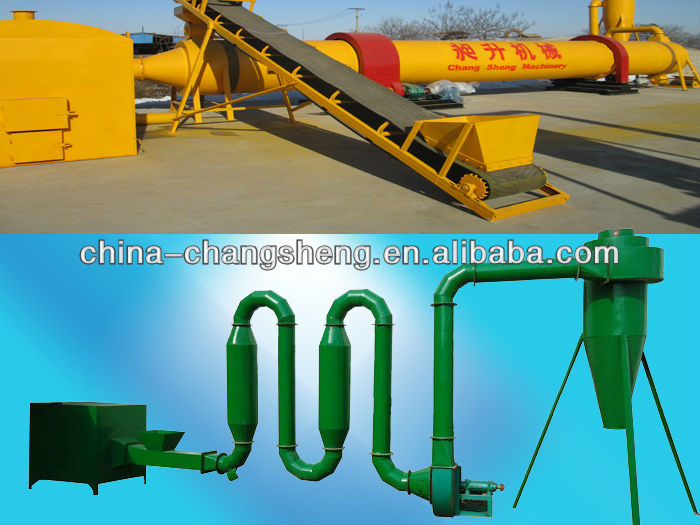

Pictures of Alfalfa Dryer used in Pelletizing:

rotary dryer

airflow dryer

Note:

If you're interested in our products, please don't hesitate to list :

1.kinds of raw material that you want to process

2.the max size of raw materials

3.theoriginalmoisture of raw materials

4.the final moisture of materials

5.output capacity or input capacity per hour

6.what is the fuel? coal, natural gas, wood or other fuel?

Then we will be able to provide you the right machine and service soon. Thank you very much!

| Packaging Detail:wood box or iron sheet |

| Delivery Detail:7-15 workdays after the order is confirmed |