Aerated Concrete Equipment AAC BLOCK

| Type:any kinds | Brick Raw Material:Concrete | Processing:Brick Production Line | Method:Vacuum Extruder |

| Automatic:Yes | Capacity:as your required | Place of Origin:Japan | Brand Name:Hengjia machinery |

| Model Number:as your required | Power:various | color:as you like | application:building,chemical industry,food, cement-- |

Aerated Concrete Equipment AAC BLOCK

1.AAC Blocks

2.mechanized construction

3.strong adaptability

4.good heat preservation

Our company is the only one on scientific research and development is given priority to, using German technology aerated concrete block equipment professional manufacturers. Full hydraulic pressure system, the computer control.

Advantages of AAC blocks:

1. Light Weight

The AAC blocks are generally weighted 550-750kg/m³, amount to 1/4-1/3 of the clay bricks and limesand bricks, and 1/5 of the common concrete bricks. The adoption of this material in the infilled walls of the high buildings and load bearing walls of the low buildings can reduce the self weight of the buildings, and thus greatly improve the anti-seismic of the buildings.

2. good heat preservation and sound insulation performance

The heat conductivity factor of the AAC blocks is 0.11-0.18kc/m0h0°C, amount to the 1/4-1/5 of the clay bricks and limesand bricks. Thus the thickness of the walls has been greatly reduced, and the effective using area can be enlarged accordingly, improving the efficiency and lowering the construction costs. Meanwhile, the closed pore structure inside the blocks helps the products have good sound absorption property.

3. strong intensity

According to tests, the compressive strength of the AAC blocks is above 25kg/cm², equal to the strength of the No.125 clay bricks and limesand bricks

4. good processing properties

The AAC blocks can be sawed, planed, nailed, milled, drilled, and added rebars in the processing.

5. in favor of mechanized construction

6. strong adaptability

The AAC blocks can be produced according to different materials and various conditions.

Raw Materials:river sand, fly ash, ore sand, cement, gypsum, aluminium powder, water, etc.

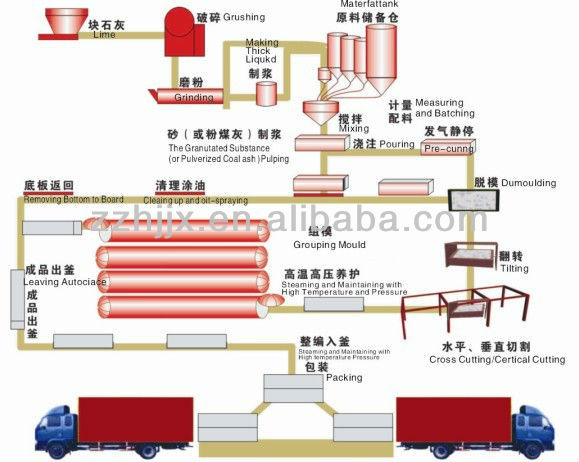

Production Process:

According to the categories and quality of raw materials, and the features of the equipments, the AAC blocks can be processed by different technology. Generally, first, add water into the fly ash or silica sand, slag and grind them to the slurry, second, add powdery lime, certain cement, gypsum, foaming agent, foam stabilizer to the slurry; after being mixed, the blender will be sent into the mould, stay there to foam and solidify; after that, it will be cut into blocks or panels varying in specifications by the cutter, then be sent into the autoclave by the hardening car, and through autoclaving with high temperature and strong pressure, finally produce the light cellular concrete products.

Above equipment installation instruction, equipment does not contain freight, packing, customs charges, including electrical appliances, equipment can according to the customer site and money to do adjustment, autoclave, boiler customers can order directly to the manufacturer.

| Packaging Detail:standard package |

| Delivery Detail:25days after received the down payment |