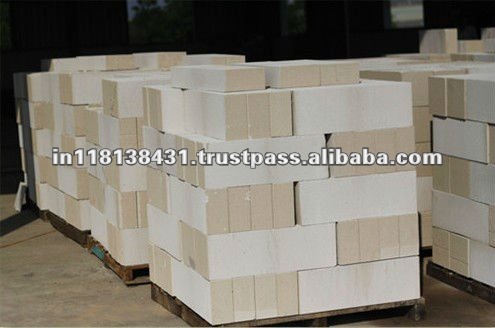

AAC Blocks Production Line

| Condition:New | Type:Block Manufacturing Machinery | Brick Raw Material:Fly Ash | Processing:Brick Production Line |

| Method:Steam | Automatic:Yes | Capacity:50,000 - 4,00,000 CBM/year | Place of Origin:Gujarat India |

| Brand Name:ANJALI | Model Number:AAC 1 | Voltage:400 V | Power:300 KW |

| Warranty:1 Year | After-sales Service Provided:Engineers available to service machinery overseas |

INTRODUCTION:

AAC is Autoclaved Aerated Concrete. The blocks are made to aerate by creating a reaction between silica in base material such as fly ash or sand, active lime, and aluminum power. The block hardness is being achieved by cement strength, and instant curing mechanism by autoclaving. Gypsum acts as a long term strength gainer.

The ANJALI VENTURES LTD. line from 50,000 CBM to 1,50,000 CBM includes the following items:

1. Production equipments and Technology of the AAC Blocks process.

2. Special lay out for your factory and One year equipment warranty.

3. Transfer of know-how with the training in your site.

4. Set up and installation in the customer facility.

TECHNICAL COMPARISON:

PARTICULARS | CONVENTIONAL RED BRICKS | FLYASH BRICKS |

| Strength | 40 – 65 Kg/cm2 | 70 – 120 Kg/cm2 |

| Shape & Size | Non Uniform & Irregular | Uniform & Regular |

| Water Absorption | 20 – 25 % | 10 – 15 % |

| Breakage / Wastage | 8 – 10 % | 3 – 4 % |

| Mortar Consumption | High | Less |

| Density | 1500 – 1700 Kg/cm3 | 1200 – 1350 Kg/cm3 |

| Nos. of Bricks for100 sq.ft. wall of 9” thick | 1100 Nos | 925 Nos. |

| Mortar Joint Thickness | 15 – 18 mm | 8 – 10 mm |

| Plaster Thickness | 15 – 20 mm | 10 – 12 mm |

Features and Benefits of AAC Blocks:

1. Environmental friendly : Consumes Fly ash |

| 2. Environmental friendly : Saves invaluable top soil |

| 3. Environmental friendly : needs no burning/backing |

| 4. Strength : Higher Strength Bricks. |

| 5. Uniform Shape : Easier and faster Brick working. |

| 6. Uniform Shape : Less Mortar in Brick work. |

| 7. Uniform Shape : Less Mortar in Plaster. |

| 8. Natural Concrete : Gains strength over time. |

| 9. Natural Concrete : Walls can be left exposed/un plastered. |

| 10. Light weight : Faster and easier transportation |

| 11. Light weight : Faster and easier brickwork |

| 12. Light weight : saves structural concrete by 35% |

POWER AND WATER DETAILS:

Total power supply: 600 KW

Water requirement: 400 liters per CBM

REMARKS:

1. Terms of payment: | 30% down payment, 70% before container loading. |

| 2. Lead time: | 2 months |

| 3. Container: | about 14pcs 40’containers |

| 4. Package uses: | large goods bulk packing, small goods and electric control parts have wooden box packing. |

| 5. After-sales service | : One year free service after successful installation. |

Contact Details:

Website : www.anjaliventuresltd.com

| Packaging Detail:Direct container packing. It will be delivered upto your site in the containers. Complete care is taken in packaging to be completely damage free. It has Fourteen 40 feet cointainers. It is sent via shipment through sea. |

| Delivery Detail:3-4 months |