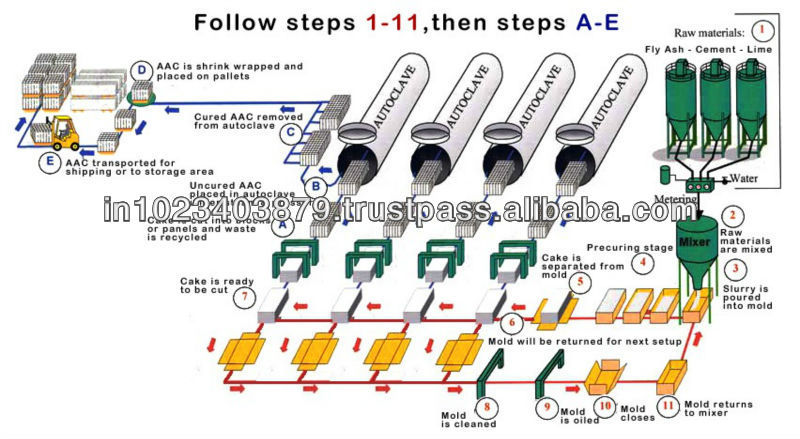

AAC Block Production Plant

| Condition:New | Type:AAC Block Plant | Brick Raw Material:Fly Ash | Processing:Brick Production Line |

| Method:Autoclaved Aerated Concrete | Automatic:Yes | Capacity:50,000 - 4,00,000 CBM/Year | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:Mingjie | Model Number:aac126 | Voltage:400v | Power:280 kv |

| Dimension(L*W*H):NA | Warranty:1 Year | After-sales Service Provided:Engineers available to service machinery overseas | Product:AAC Block Machinery |

| Technology:Latest german technology | Production:Flexible with higher productivity | Raw Material:Fly ash, Lime, Cement, Gypsum, Aluminum Powder | Installation:By our experts |

| Curing:Steam curing in autoclaves | Automation:Yes | Training:By our engineers | Service:free after sales service for one year |

| Packaging Detail:In Containers |

| INTRODUCTION: We are pioneer supplier of Autoclaved Aerated Concrete(AAC) Block Making Machinein India. We have a Joint Venture withChangzhou Mingjie Building Material Equipment Manufacturing Co. Ltd., China. We are providing local facility for AAC Plant including service, installation, training, testing and spare house. We have a team of experts in for installation, professional training, services amd guidance. |

| Autoclaved Aerated Concrete (AAC) Block Making Machinesare fast catching up the market thanks to the benefits it offers. In India, where major source of power is coal based thermal power plants, the disposal of fly ash (residual byproduct of the thermal power plant) becomes the case of concern. |

| Since, fly ash accounts for the 70% of the raw-materials ofAAC Block Making Machine. It solves the problem of disposing the fly ash, by-produced in coal based thermal power plant. In fact, it utilizes the same in more productive manner. So, in countries like India, Government promotes the business ofAAC Block Making Machine. Moreover, it offers the host of other benefits, which the red brick doesn’t offer to entrepreneurs and the end users. |

| AAC Block Block Machine Advantages: 1. Consumes Fly ash, which is a big problem for thermal power plants to dispose. It is environment friendly, because of no need of burning. 2. Higher strength, best thermal insulation & excellent sound absorption, vibration resistance compared to red bricks. The AAC product’s lightweight and easy workability means that is very quick to install on site and transportation with lesser brakeage. 3. AAC blocks made walls can be left exposed (without Plaster) and gains strength over time. It saves structural cost by 35% and recycling of breakage, rejects also. 4. AAC products are not affected by harsh climatic conditions and will not degrade under normal atmospheric conditions. 5. AAC Block does not have any toxic substances or emit odors. Its production, management and disposal do not represent any health risks or damage to the environment. Its production process develops non-toxic gases. 6. AAC blocks are bigger in size then conventional bricks, resulting in lesser number of joints. Less joints result in lesser quantity of mortar required, resulting in saving of mortar. |

| The ANJALI VENTURES LTD. line from 50,000 CBM to 4,00,000 CBM includes the following items: 1. Production equipments and Technology of the AAC Blocks process. 2. Special lay out for your factory and One year equipment warranty. 3. Transfer of know-how with the training in your site. 4. Set up and installation in the customer facility and after sales service and warrnaty of machinery. |

TECHNICAL COMPARISON:

|

Features and Benefits of AAC Blocks:

|

| Packaging Detail:Container Packing. |

| Delivery Detail:4 Months |