50 ton per hour iron ore processing equipment separation process

| Type:Mining Thickener | Condition:New | Application:Iron ore separating | Production Capacity:50t/h |

| Place of Origin:Henan China (Mainland) | Brand Name:Songshan | Certification:CE&ISO&CCC | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Drawing document:Supply | Installation:Our engineer guide | Staff training:Supply |

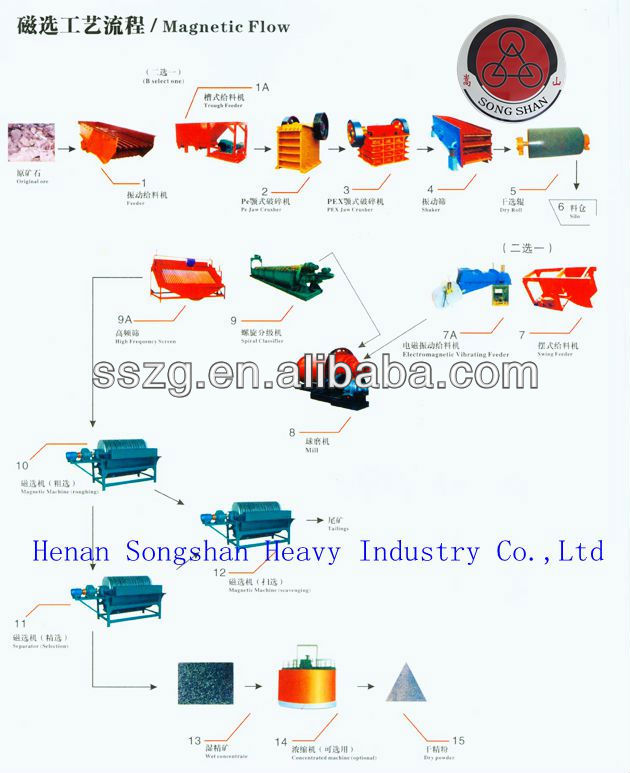

Oreflotation separation processis mainly composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, drier, feeder, and conveyor etc.

Advantages: high efficiency, low energy cost, high production capacity and economy and rationality.

Procedure of ore flotation separation process:

1) The ore is first sent to the jaw crusher for primary crushing.

2) Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding.

3) The ore powder discharged from the ball mill will be sent to the next procedure: classifying.

4) Because of the different sedimentation rate due to the varied specific gravity, spiral classifier can clean and group the ore mixture.

5) The cleaned and grouped mixture is sent to magnetic separator, due to the different susceptibility, magnetic substance can be separated from the mixture under magnetic and mechanical force.

6) Then the mixture is sent to flotation machine. According to the features of different ores, we can add different additive into the mixture to separate the ore which we want from the mixture.

7) After the separation from the mixture, the ore we want always contains a lot of water, then we need a thickener to have it concentrated and then dried by a drier, eventually we can get dry ore.

| Packaging Detail:Standard container,bare main machine, motor and spare part are packed in wooden case. |

| Delivery Detail:35-40 working days after receiving your down payment |