50% dfiscount pomace dryer made in china for your best choice

1.Rotary body, lifting blade, 2.Driving device, supporting device, 3.Sealing ring, reliable performan, 4.ISO,CE, 5.Value drying - details see: https://www.machineto.com/50-dfiscount-pomace-dryer-made-in-china-for-your-best-choice-10288036

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Superior |

| Model Number:Model S4598 | Voltage:as your demands | Power(W):as your demands | Dimension(L*W*H):our engineer design |

| Weight:as your demands | Certification:ISO | Warranty:for whole using time,2 years for free | After-sales Service Provided:Engineers available to service machinery overseas |

| Color:as your demands | Gradient of Rotary Dryer:3-5% | Rotary Dryer OEM Service:supply | efficiency:high envirenmental |

1. Biomass Drying Machine Main Usage:

- Biomass drying machine can be used for drying lots of material once, and can achieve better drying effect. As professional wood chip dryer machine manufacturer, we guarantee you the quality of rotary dryer. Guoxin rotary dryer has approved CE certificate. Our engineer always pay much attention on update dryer technology, and we are enriching our strength all the time. What's more, we have exported our wood chip dryer machine to Philippine, Canada, Italia and some other country.

- It widely used on Metallurgy, Industries of cemet, Light industry, Mine, Contruction, Chemical industry, Coal and Compoud fertilizer field.

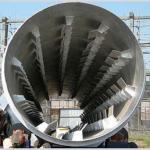

2. Main Constructions of Biomass Drying Machine:

- Superior factory biomass drying machine consists of following parts:

| 1. Adjustable Motor | 2. Reducer | 3. Transmission Base | 4. Big Gear |

| 5. Small Gear | 6. Tug Base | 7. Feed Port | 8. Discharge Port |

| 9. Air Induced Fan | 9. Air Induced Fan | 11. Roller Ring | 11. Roller Ring |

Feed port and discharge port of biomass drying machine are installed with thermocouple, it can control dryer temperature. The changing temperature of dryer can be indicated by thermometer, then the operated workers can get to know the inner dryer temperature

3. Technical Specification of Biomass Drying Machine:

4. Working Principles of Biomass Drying Machine:

- Biomass drying machine is suitable for drying various types of sawdust which the moisture content is less than 55%.

- 1. First, wood chip after transfer system enter into the biomass drying machine cylinder, flied by raising plate device which are uniform distribution in the drum cylinder.

- 2. The biomass are evenly distributed in biomass drying machine cylinder, then fully contact with the hot air, speed up the drying heat and mass transfer.

- 3. During the drying process, under the effect of raising plate and hot treatment inside biomass drying machine cylinder, the materials are dryed well.

- 4. At last, the dried wood chip come out from the end of the biomass drying machine.

5. Superior Features of Biomass Drying Machine:

- (1) The cylinder use toprank quality Q345R carbon steel which can bear the highest temperature.

- (2) Biomass drying machine with simple & excellent structure which can help material run smoothly through the cylinder & to prevent materials blockage problem.

- (3) Low coal consumption which can save energy more than 10%.

- (4) Biomassdrying machine is easy to operate, a complete drying system only just need 3 worker.

- (5) Working stable largely boost wood drying effect at short time.

- (6) Easy maintainance with long service life.

| Packaging Detail:Standard container with 40GP,40HP or in bulk, small parts are packed in wooden case. |

| Delivery Detail:Within 20 working days after receiving advanced payment |