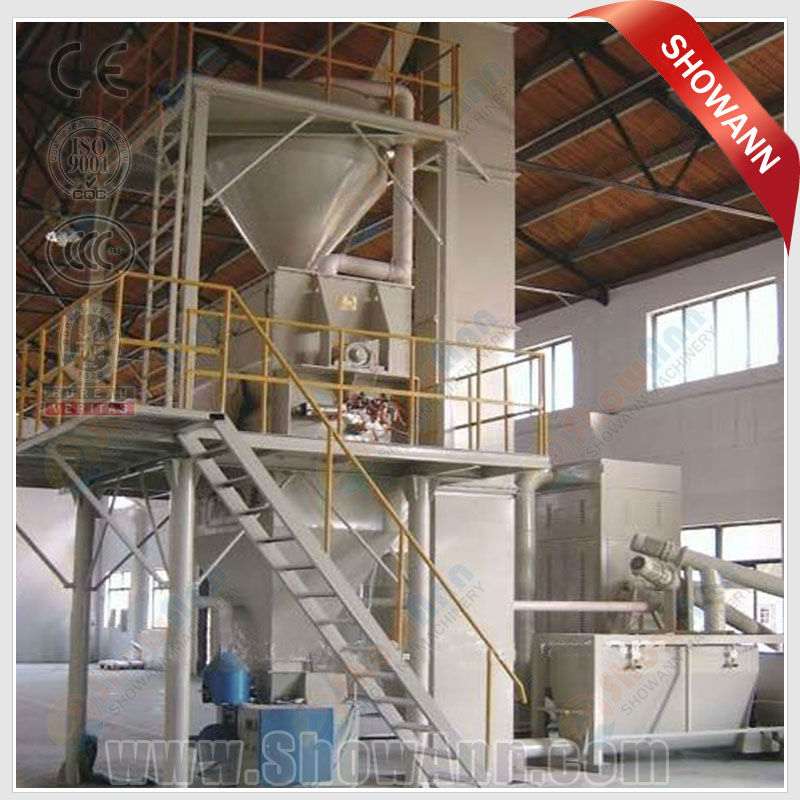

5-10t/h Dry mortar mixing plant

| Condition:New | Application:make all kinds of mortars,for all construction | Production Capacity:5-10T/h | Place of Origin:Henan China (Mainland) |

| Brand Name:SHOWANN | Model Number:SADM-10 | Voltage:380V | Power(W):22.5KW |

| Dimension(L*W*H):L*K*H | Weight:1500kg | Features:easy operation | Certification:ISO,CE |

| Warranty:12months | After-sales Service Provided:Engineers available to service machinery overseas | name:5-10t/h Dry mortar mixing plant | type:basic types |

| capacity:10t/h | motar types:masonry mortar,therminal motar etc. | warranty time:12months |

5-10t/h Dry mortar mixing plant

Dry mortar production line is also called pre-mixed mortar producton line, which made in the factory by precise batching and uniform mixing. It can be used directly just by adding water in construction site. It has different properties though adding different additives. The demand for dry mortar production line has increased rapidly due to its outstanding merit compare to the mortar production linemade in job-site.

Type of5-10t/h Dry mortar mixing plant:

1. Bonding mortar: masonry mortar, wall and floor tile adhesive mortar, pointing mortar, anchorage mortar etc.

2. Decoration mortar: plaster mortar, inner and outer wall putty, colorful decoration mortar etc.

3. Protection mortar: water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, insulation mortar, sound absorption mortar, repair mortar, mildewproof mortar, shielding mortar etc.

Raw materials of5-10t/h Dry mortar mixing plant:

1. Cementing material: cement, lime, plaster.

2. Aggregate: yellow sand, quartz sand, limestone, dolomite, expanded perlite etc.

3. Mineral admixture: industrial byproduct, industrial slag, fly ash, pozzolana, fine silica powder etc.

4. Water-retention and thickening material.

5. Chemical additives.

Main equipments of5-10t/h Dry mortar mixing plant:

Raw material storage silo, sand dryer, bucket elevator, spiral conveyor, weighing system, mixer, end product silo, packing system, dedusting system, computer control system, air compressor, air-phase balance system,steel structure,

Parameter of5-10t/h Dry mortar mixing plant:

| Production line mode | Output | Occupied area | Equipment height | Remark of batching and packing |

| Simple | 1-15t/h | 40m2 | 5-10m | Manual batching and packing |

| Basic | 5-15t/h | 40-60m2 | 6-10m | Manual batching, automatic packing |

| Semiautomatic of serial mode | 5-15t/h | 40-80m2 | 8-12m | Automatic batching of coarse material, manual batching of additive, automatic packing |

| Semiautomatic of tower mode | 5-50t/h | 40-100m2 | 10-25m | the same to serial semiautomatic mode |

| Fully automatic of tower mode | 5-50t/h | 60-500m2 | 10-25m | Automatic batching of all raw material and packing |

PLS contact us for any detailed information about the price, freight,packing or any other question! Waiting for you enquiry!

5-10t/h Dry mortar mixing plant

| Packaging Detail:standard export packing |

| Delivery Detail:10-15working days once get the payment |