5-10T/D Sunflower/Peanut/Cottonseed/Soybean oil refinery machine

| Condition:New | Usage:various seed,like peanut,soybean,sunflower,Various crude oil, rice bran oil, sunflower oil etc | Type:Oil refinery to get refined | Automatic Grade:Automatic |

| Production Capacity:As per capacity of crude oil refinery | Place of Origin:Henan China (Mainland) | Brand Name:HONMAC | Model Number:Oil refinery to get refined |

| Voltage:220V/380v; As per your request | Power(W):As per capacity of crude oil refinery | Dimension(L*W*H):As per capacity of crude oil refinery | Weight:As per capacity of crude |

| Certification:CE,SGS,BV,ISO9001:2008, | After-sales Service Provided:Engineers available to service machinery overseas | Refined oil standard:1st, 2nd, 3rd,4th oil ; as per your request | Material of equipment::Carbon steel and stainless steel |

| Raw material::Various crude oil | Capacity of oil refinery:100T/D ; 10-800 T/D all available | Application::Improving oil quality | Heating way:Heat conduction oil, or steam |

| Dimension(L*W*H)::As per capacity of crude oil refinery | Refining technics::Continuous, semi-continuous | Oil refinery process:Degumming,bleaching,deacidfication,deodorization,dewaxing |

5-10T/D Sunflower/Peanut/Cottonseed/Soybean oil refinery machine

1. Introduction of oil refinery machine:

1.The oil refinery machine is used for removing the impurities of oil, such as, fatty acid, phosphatide, metal ion, pigment, oxide, solid particle and volatile gas. It suitable for refining various crude oil, vegetable oil, such as sunflower seed oil, tea seed oil, groundnut oil, cottonseed oil, rice bran oil, soybean oil, corn oil and palm oil,etc.

2.The oil refinery machine can adopts chemical refining and physical refining, and the chemical refining includes batch refining, semi-continuous refining and continuous refining.

2. Advantage of oil refinery machine:

1. Less power consumption

2. Include installation & debugging

3. Best edible oil refinery machinery

4. Best long-term after-sale service

3. Main equipments of oil refinery machine:

1. Neutralization Tank: used for acid refining, alkali refining or washing.

2. Bleaching Tank: used for bleaching oil & removing pigment.

3. Deodorizing Tank: used for removing the odour of oil (made of stainless steel).

4. Conduction Oil Furnace: provide production with heat source, and the temperature can

reach 280 °C.

5. Vacuum Pump: provide vacuum degree for bleaching & deodorizing process, which can reach above755mmHg

6. Air Compressor: weather bleaching earth used in the bleaching process

7. Filter Press: filtrate the bleaching earth

8. Steam Generator: produce steam for deodorization and distillation process

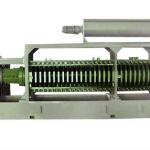

9. Leaf Filter:filtrate the bleaching earth & impurities.

4.ProcessCartofoil refinery machine:

1. Degumming:Removing the phosphatide by adding hot water, when phosphatide meets hot water, it will become bigger and bigger, then out of tanks.

2. Deacidification:Removing the FFA by add caustic soda (for taking neutrallzation reaction).

3. Bleaching: Remove the pgment by adding bleaching earth( it has srtrong adsorption of pigment), and the remaining bleaching earth will be filtrated by leaf filter.

4. Deodorization:Remove the oxide, solid particle and volatide gas.

5. Spares parts of oil refinery machine:

| Packaging Detail:high quality wood case of oil refinery machine |

| Delivery Detail:40-50 days after prepayment of oil refinery machine |