44 years manufacture diversity models screw conveyor for silo cement

| Place of Origin:Hubei China (Mainland) | Brand Name:SANFAN cement silo | Model Number:80ton | Color:As your request |

| Tanker Diameter:3m | Tanker Height:9m | Matched mixer:JS750 | Screw Conveyor:LSY180 |

| Use:Construction project | Tank Total Height:13m | volume:80ton | brand:SANFAN |

| name:cement silo | Condition:New | Material:Steel | Capacity:80ton |

44 years manufacture diversity models mini cement silo for sale,cement silo price,cement silo manufacturers

Brief Introduction:

1.With44 yearsconstruction machine manufacture & sales experience, now SANFAN grows into a famous brand in China with everyone's join efforts.

2.Main products:

elavator,concrete pump,steel bar machine,water pump,mixing plants,construction vehicle,road machine,batching machine, cement silo ,concrete mixer,rammer,concrete vibrator etc....

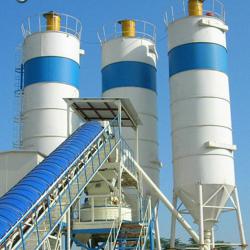

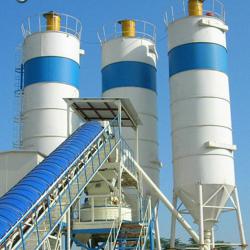

Description Of cement silo

Concrete mixing plant is composed of material supply,batching

system,mixing,electrial control and steel structure

1.main technical parameters of cement silo

| Model | Tanker Diameter | Tanker Height | Tanker Total Height | Matched mixer | Matched screw conveyor |

| 30Ton | 2.6m | 4.8m | 12m | JDC350 | LSY163 |

| 50Ton | 3m | 5.4m | 12m | JS500 | LSY180 |

| 80Ton | 3m | 9m | 15.6m | JS750 | LSY180 |

| 100Ton | 3m | 11.4 | 18m | JS1000 | LSY230 |

| 150Ton | 3m | 13.5m | 19m | JS1000 | LSY230 |

| 200Ton | 4.5m | 18.6m | 25.2m | JS1500 | LSY230 |

| 300Ton | 4.5m | 24.6m | 29.5m | JS2000 | LSY230 |

Note: The above technical parameters are just for your reference.

Advantage:

1. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

2. High degree of standardization. We can produce the standard components which can be installed on-the-spot.

3. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

4. Easy to understand. The bolted silo is equipped with relevant accessories, such as: conveyor, ventilation, drying and monitoring devices, etc. to ensure the quality and safety of the material stored in the silo.

5. Easy to maintain. As the parts of the silo are connected by standard bolts, so it is easy to remove or repair it.

6. Low cost and long tenure of use. The cost of bolted silo is just 35%-50% of the cement silo with the same specification; and its life span can reach 30 years.

After get your detailed requirement, we will supply professional design and offer, for your inspection :)

Manufactured Technology of Cement Silo:

The parts of the cement silos are manufactured by special laser cutting and drilling technologies and they are implemented

special surface cleaning procedure. The parts of the cement silos also are manufactured in sensitive production facilities

with special equipments and they are painted with prime coating and final coating. The parts which are hung on automatic

conveyor line , are painted inspecial painting cabinets. Then the parts of the cement silos are packed specially suitable for

transportation.

Features of detachable cement silo:

1. Our cement silo is detachable, so it is easy for transportation;

2. Mainly used as a cement storage tank of Concrete Mixing Plant;

3. It is a sealed silo for bulk storage object, suitable for storing grain, cement, fly ash, etc.

4. It can be equipped with level indicator so as to monitor the material level and amount.

5. With the screw conveyor, the materials can be conveyed to a certain position.

cement silo:

| Packaging Detail:stardard packing |

| Delivery Detail:within 10 days |