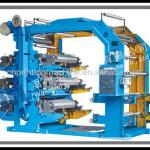

4 Colors Flexographic Printing Machine

| Type:Flexographic Printer | Condition:New | Plate Type:Letterpress | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:changhong | Model Number:CR884-800 | Usage:plastic film | Automatic Grade:Automatic |

| Color & Page:Multicolor | Voltage:22/380V,3P | Gross Power:45kw | Dimensions(L*W*H):4.8m*2.2m*2.6m |

| Weight:5.0T | Certification:CE | Printing Speed:80m/min | Flexographic Printing Machine:Flexographic Printing Machine |

| anilox roll:ceramic anilox roll | Ink runnnig way:Enclosed chambered doctor blade | ink cycle:Two-way diaphgram pump | tension control:auto tension control |

| EPC:edge position controller |

4 Colors Film Flexographic Printing Machine

The main features:

1. Take it easy, accurate color, long life

2. The use of motors, variable frequency speed control, saving electricity, running small fluctuations

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink

4. The use of special diagonal-tooth gear, print size is accurate,

5. There are two sets of heating devices, including central heating and constant temperature control system for packet control

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium

7 Alloy roll with hard oxidation, treating by dynamic balance, static balanced

8 With a cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. The Print produce are clear and good arrangement quality

10.Bearing: NSK, Japan brand, Germany ASNU aluminum alloy roll

Main Technical Parameter:

CR Series:

1.Printing Material:Plastic film, paper (20-100g/m2)

2.Max. Material width:600-2000mm ( Actual width decided by client)

3.Max. Printing width:560-1960mm ( Actual width decided by client)

4.Printing Length (Repeat):7.5"~40"(190mm~1000mm)/7.5"~50"(190mm~1270mm)

5.Max. Machine speed:150m/min (3standrds: 80m/min, 120m/min, 150m/min)

6.Max. Printing speed:130m/min (3standrds: 60m/min, 100m/min, 130m/min)

7.Thickness of Plate (include the glue) :2.28+0.38mm

8.Register precision:Longitude:±0.15mm Transverse:±0.15mm

9.Machine power:40KW

10.Machine dimension:5.0m× 2.2m×2.8m

Unwind Unit:

1.Unwind DIA.:Φ1000mm

2.Unwind way:By cylinder, load the material by automatically

3.EPC system for unwind:Edge Position Control, 1 Pcs

4.Tension system for unwind:Automatic tension control, 1PCS

5.Material hold way for unwind:By air shaft , 1pcs;

6.Unwind web cylinder:Φ76mm (inner diameter)

Traction Unit:

1.Constitution of Traction:Rubber Roller and Chrome plated Roller

2.Traction Zones:2 Zones

Printing Unit:

1.Constitution of Printing:Chrome plated Roller, Rubber Roller, Anilox roller, Plate-glued roller

2.Girth of Pressing Roller:7.5"~40"(190mm~1000mm)/7.5"~50"(190mm~1270mm)

3.Material of Plate:Resin and Rubber

4.Principle of Work:Gears Drive

5.Way of Adjusting:By manual

6.Plated-glued roller adjusting:By hydraulic

7.Printing Pressure:Mechanical adjust

8.Anilox roll:Ceramic anilox roll , 4 pcs

9.Doctor blade:Enclosed chambered doctor bladew 4 Pcs (Imported Part)

10.Inksupply pump:Two-way diaphragm pump, 4pcs

11.Master motor:3.7Kw, Taiwan Brand

12.Inking motor:60W, deceleration motor

Heating and Drying Unit:

1.Drying way :Electrical heat drying

2.Type of Heating and drying:blowing first then heating

3.Heating Zones:Heating Tubes 4colors 6zones

4.Power of Heating:2.2kw

5.Blowers:21 Fans

6.Power of Blowers:0.95kw×6pcs; 75w×15pcs

7.Drying power:25kw

8.Master frequency converter:3.7 kw (CHINA)

Rewind Unit:

1.Rewind DIA:Φ1000mm

2.Rewind way:Central rewind

3.Tension system for rewind:Automatic tension control, 1PCS

4.Material hold way for rewind:By air shaft , 1pcs;

5.Rewind web cylinder:Φ76mm (inner diameter)

6.Rewind motor:1.5KW

Optionalparts (need buy extra cosr):

1.Corona treatment

2.Image inspection device

3.Printing cylinder

| Packaging Detail:as required |

| Delivery Detail:60 days |