3T building travelling crane supplier

| Feature:Tower Crane | Condition:New | Application:Tall Buildings, Roads, Bridges | Rated Loading Capacity:3t |

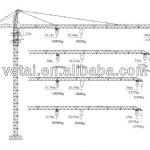

| Rated Lifting Moment:315KN*m | Max. Lifting Load:3T | Max. Lifting Height:28m | Span:3 to 42m |

| Place of Origin:Henan China (Mainland) | Brand Name:UNIQUE | Model Number:QTZ31.5 | Certification:CE, ISO |

| Warranty:15 months | After-sales Service Provided:Engineers available to service machinery overseas | model:QTZ31.5(4208) | max load:3T |

| tip load:0.8t | boom length:42m | max lifting height:28m | slewing speed:0.6r/min |

| jack up speed:0.55m/min | derricking speed:0~60m/min |

Abroad Travelling Tower Crane Engineering Projects

1.Tower crane installed in Russia

2. Tower crane installed in philippines

Components of Building Travellingcranes

slewing system of Building travelling crane

cross beam fix the foundation of building trvelling cranes

Tower body parts of building travellingcrane

Features of building travelling crane

I. The tower crane is a combination of advanced technologies of the present day. Its key parts use Q345 steel. Not only is the tower crane equipped with a hydraulic self-raising mechanism, but also its three key mechanisms (hoisting, slewing and radius-changing mechanisms) are all driven by frequency-converting motors.

II. The electric control system of the tower crane adopts the advanced PLC + frequency converter control mode of the present day, which has realized the stepless speed regulation and greatly improves the reliability, maneuverability and stability of the control system and the work efficiency of the tower crane.

III. The tower crane is equipped with all kinds of reliable safety devices, such as hoisting height limiter, slewing range limiter and multifunctional limiter to control the load moment, hoisting capacity and trolley traveling range. Its PLC (Programmable Logic Controller) unit can diagnose the cause of breakdowns. Its Safety Monitoring System (also known as Black Box) displays the data of working radiuses, heights, moments and weights.

IV. The use of world-famous electric components such as OMRON, YASKAWA, Schneider (TE) and MEAN WELL greatly reduces the failure rate of the electric control system and improves the work efficiency of the users.

V. There are also electric safety devices like anemoscopes and obstacle lights and mechanical safety devices to prevent the breaking of trolley axles and wire ropes.

Technical parameter of QTZ31.5 travelling crane

Type | QTZ31.5(TC4208) | |

Rated lifting moment | 31.5 KN. m | |

Max. Lifting load | 6t | |

Working radius | 3~60m | |

Tip load | 1.3t | |

Hoisting height | Independent | 46m |

| Attached | 214m | |

Hoisting speed | 2 falls | 60m/min |

| 4 falls | 30m/min | |

Trolleying speed | 0~58m/min | |

Slewing speed | 0~0.6r/min | |

Climbing speed | 0.55m/min | |

Structure self-weight | 12t | |

Balance weight | 20t | |

Allowed temperature | -20~40°C | |

Working voltage | 380±5% v | |

| Packaging Detail:standard export packing for travelling crane |

| Delivery Detail:30days after receipt down payment of travelling crane |