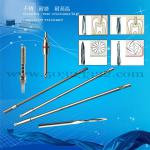

3mm Solid Carbide Right Hand Helix Reamer / Machine Reamer

| Place of Origin:Jiangsu China (Mainland) | Brand Name:SJ/LMK/DHN | Model Number:3D*15*60L | Material:Tungsten Steel |

| Type:Chucking Reamer | Diameter:3mm | Blade Length:15mm | Overall Length:60mm |

| HRC Grade:45HRC |

3mm Solid Carbide Right Hand Helix Reamer / Machine Reamer

Changshu Sanjun Precision Cutting Tools Manufacturer is a professional manufacturer of cutting tools. Our end mills enjoy good reputation both at home and abroad.

The following is our product specifications.

| specification (mm) | balde length (mm) | overall length (mm) |

| 3 | 15 | 60 |

| 4 | 19 | 75 |

| 5 | 23 | 85 |

| 6 | 26 | 90 |

| 8 | 33 | 110 |

| 10 | 35 | 130 |

| 12 | 45 | 150 |

We can customize end mills according to your request.

Looking forward to having a long time cooperation with you.

If you have any need, please contact me at any time!

Thanks!

Chip information

Although there are many different types of milling cutter, understanding chip formation is fundamental to the use of any of them. As the milling cutter rotates, the material to be cut is fed into it, and each tooth of the cutter cuts away small chip of material. Achieving the correct size of chip is of critical importance. The size of this chip depends on several variables.

• Surface cutting speed (Vc): This is the speed at which each tooth cuts through the material as the tool spins. This is measured either in metres per minute in metric countries, or surface feet per minute (SFM) in America. Typical values for cutting speed are 10m/min to 60m/min for some steels, and 100m/min and 600m/min for aluminum. This should not be confused with the feed rate.

• Spindle speed (S): This is the rotation speed of the tool, and is measured in revolutions per minute (rpm). Typical values are from hundreds of rpm, up to tens of thousands of rpm.

• Diameter of the tool (D):

• Feed per tooth (Fz): This is the distance the material is fed into the cutter as each tooth rotates. This value is the size of the deepest cut the tooth will make.

• Feed rate (F): This is the speed at which the material is fed into the cutter. Typical values are from 20mm/min to 5000mm/min.

• Depth of cut: This is how deep the tool is under the surface of the material being cut (not shown on the diagram). This will be the height of the chip produced. Typically, the depth of cut will be less than or equal to the diameter of the cutting tool.

| Packaging Detail:plastic pipe package |

| Delivery Detail:within 30 days |