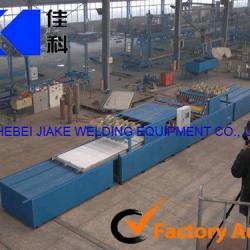

3D panel machine

| Place of Origin:HEB,Hebei,China China (Mainland) | Brand Name:JIAKE | Model Number:JK-1200B | Certificate:CE, ISO9001 |

3D panel machine

3D panel adopts 3-dimension spatial steel wire mesh frame as the framework, anti-flaming polystyrene (EPS) foam panel as heat protective core layer. External layer of the wall building material is sprayed with the pea gravel concrete or slush. The automatic production line of 3 Dimensional, adopt PLC control system with touch screen, by pneumatic and stepping motor power, via auto oblique joint and cut off, the strict fixing of flat mesh and foam panel, the combined welding of oblique cutting wire and flat mesh, to finish the produce of iron wire mesh frame polystyrene sandwich panel. It has following character: automation production, high productivity, loss welding rate, large strength of welding point, welding uniformity, good surface, and the production cost is very low. The equipment has good maintainability, stability and reliability.

Main Parameter:

rated electrical power | 75KVA | ||

input voltage | AV380V 50HZ | ||

Air source allocation | 3 Cubic meter/Min 0.6MPa | ||

Applicable range | Core panel thickness | 50mm-100mm | |

Truss wire configuration | Single or double sided mesh ,different densities of truss wires | ||

production standard | Standard Sandwich panel | length | 3000mm |

| width | 1220mm | ||

nonstandard sandwich panel | The length according to your requirement ≤4500mm | ||

material characteristic | Welded wire material | 2.0mm-3.0mm cold-drawing low-carbon steel wire | |

Core panel material | Anti-flaming EPS board & XPS board | ||

Gridding space of mesh | 50mm*50mm | ||

lack welding rate | ≤5% | ||

welding strength | (single point)≥330N | ||

overall dimension | length | 13500mm | |

| width | 1800mm | ||

| height | 1700mm | ||

weight | 4000kg | ||

| Packaging Detail:Container |

| Delivery Detail:30 days in receiving down payment |