30T/D NPK fertilizer plant/fertilizer granulating plant/fertilizer production line

| Condition:New | Application:fertilizer making,organic or NPK fertilizer making | Production Capacity:50t/d | Place of Origin:Henan China (Mainland) |

| Brand Name:Dingsheng | Model Number:DS-50 | Power(W):25kw | Dimension(L*W*H):20x10x5m |

| Weight:25t | Features:granulator | Certification:ISO9001 | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | capacity:50t/d | Brand:Dingsheng | Origin:Henan,China |

| Raw material:animal manure or waste,etc | Certificate:ISO | Eport areas:Asia,America,Oceania,Europe,Africa |

NPK fertilizer plant/fertilizer granulating machine/fertilizer production line

1.Structure : the organic compound fertilizer production line equipments mainly includes the following machines:crusher, granulator, rotary dryer, rotary cooler, screening machine, vertical mixer, belt conveyor, fertilizer coating equipment and packaging machine.

2.Material :Organic fertilizer production line use poultry dung, pig manure as its raw material which contains no chemical elements. Compound fertilizer production line uses DAP,MAP,UREA,KCL etc. as it's raw material

Wide application scope:

1. Agricultural waste: straw, dregs of beans, cotton dregs, rice bran,etc.

2. Animal manure: mixture of poultry litter (PL) and animal waste(AW),such as,Slaughterhouse Waste,Fish Market,Urine and dung of cattle,Pigs,Sheep,Chicken, Ducks, Geese,Goat.etc.

3.Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue etc.

4. Home scrap: food waste, bones, the roots and leaves of vegetables, etc.

5. Sludge: the sludge of the river, the sewer, etc.

Introduction to this fertilizer production line:

1. First, use the crushing machine to crush the material into small pieces.

2. Second, use the mixing machine to mix the material together on average.

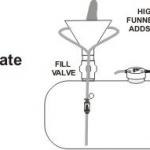

3. Third, the disc granulator or the drum granulator can make the material into granules.

4. Fifth, then the irregular granules will be screened through the screening machine.

5. Sixth, the drying and cooling machine will dry the and cool the granules. And then be packaged in bags.

The pictures of the fertilizer production line:

1 Crushing machine

2.Mixing machine

3.Disc granulator

4.Dryer

5.Cooler

6.Screening machine

7.Packing machine

8.Belt conveyor

The flow chart pictures:

We have different capacities in accordance with your requirement,please contact me

freely if you have any questions.

| Packaging Detail:wooden boxes or container |

| Delivery Detail:30 days after prepayment |