25m3/h Concrete Plant for sale with cheap price

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:LUTONG | Model Number:HZS25 |

| Production:25m3/h | Mixer:JS500 | Dosing Machine:PLD800 | Total Power:60kw |

| Discharging Height:3.8m | Total Weight:25t | Nominal Capacity:0.5 | Aggregate:2% |

| Water:1% | Cement:1% |

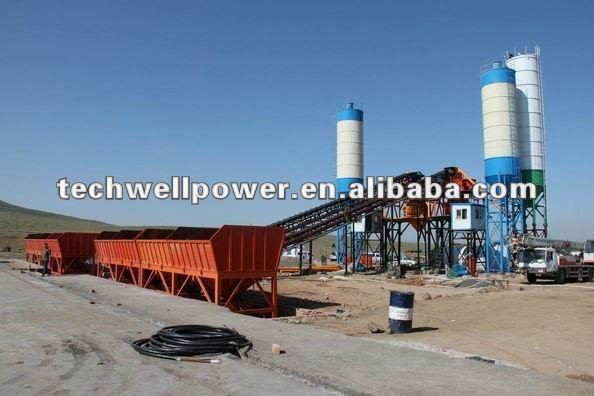

25m3/SMALL CONCRETE BATCHING PLANT

--- your construction partner!

PARAMETERS

| MODEL | Production (m3/h) | Plant Model | Nominal Capacity of Plant | Dosing Machine Model | Total Power (kW) | Measurement Precision(%) | Discharging Height (m) | Total Weight (t) | |||

| Aggregate | Water | Cement | Additive Liquid | ||||||||

| HZS25 | 25 | JS500 | 0.5 | PLD800 | 60 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 25 |

| HZS35 | 35 | JS750 | 0.75 | PLD1200 | 70 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 28 |

| HZS50 | 50 | JS1000 | 1 | PL1600Q | 100 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 40 |

| HZS60 | 60 | JS1000 | 1 | PL2400Q | 100 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 50 |

| HZS75 | 75 | JS1500 | 1.5 | PL2400Q | 110 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 46 |

| HZS90 | 90 | JS1500 / LJS1.5 | 1.5 | PL2400Q | 132 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 60 |

| HZS120 | 120 | LJS2.0 / MAO2000 | 2 | PL3200Q | 200 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 80 |

| HZS150 | 150 | LJS3.0 / MAO3000 | 3 | PL4800Q | 220 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 4 | 100 |

| HZS180 | 150 | LJS3.0 / MAO3000 | 3 | PL4800Q | 329 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 120 |

| HZS240 | 240 | LJS4.0 / MAO4000 | 4 | PL4800Q | 480 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 160 |

| 2HZS25 | 50 | JS500 | 2×0.5 | PLD800-Ⅲ | 119 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 56 |

| 2HZS35 | 70 | JS750 | 2×0.75 | PLD1200-Ⅲ | 129 | ≤±2 | ≤±1 | ≤±1 | ≤±1 | 3.8 | 56 |

DRAWINGS

COMPOSITIONS

| 1 | Aggreate Feeder System A. 4 bunkers layed in alignment while bottom in cone-shape. B. Bunkers are equipped with 2 discharging valves. C. Vibration devices to ensure full and smooth discharging. D. All measurement systems for bunkers are separate. | |

| 2 | Belt Conveyor Sytem A. 18D Slope Belt Conveyor used for deliver aggregates. B. Conveyor=driving cylinder+bracket+roller+belt+cover. C. Dual-direction Pulling Switches used for emergency. | |

| 3 | Powder Storage & Delivery System A. Suitable storage devices shall be selected. B. Powder Silo shall be 50t, 100t or 200t. C. Level gauge+Dust collector+Safety valve+Broken device. D. Sprial conveyor size: Φ219mm, Φ273mm, Φ323mm. | |

| 4 | Dosing Measurement System A. This system including water, powder and additive liquids. B. All materials adopts separate measurement systems. C. Big gauging capacity for different production demands. D. Sensor, butterfly and ball valve must be best quality. | |

| 5 | Mixing System A. Reliable mixer with famous main parts like blade. B. Full consideration of liquidics and Friction Mechanics. C. Multi-blades + Unique P/N spiral + Strong Votex Flow D. Cr cast iron as raw material of blade and lining. E. Labyrinth gland + Oil Pressure gland + Selant Gland. F. Heavy duty design reaches stable operation. G. 380V strong motor ensure fast lubrication to shaft end. | |

| 6 | Dust Collecting System A. Bag dust collector is selected in main building. B. Canvus material used to lower cost and easy operation. C. Bag collector shows good flexibility and better sealing. | |

| 7 | Control System A. Deligant control system allows full digital production process. B. WINDOWS basis control system. C. Multi tasks, multi operation window, multi users. D. Touch screen + control system ensures RELIABLE priority. E. Upper computer realizes full monitoring of plant operation. F. All parameters, data, status transffered synchronisingly. G. Simulation indication shows synchronisingly for easy control. | |

| 8 | Main Building A. Good performance H steel are used for main building structures. B. Strong structure and stable foundation with easy installation. C. Outer sealing devices makes noise, dust, hot weather free. D. Full consideration of enough inner living maintainance spaces. |

CONTACT ME, let's talk in detail................

FRANK's here waiting for your kind inquiry

| Packaging Detail:Seaworthy in container / bulk ship |

| Delivery Detail:2~3 weeks after DP |