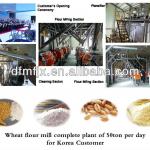

250 T Corn roller mill , Corn processing plant

| Condition:New | Place of Origin:Hebei China (Mainland) | Brand Name:HBA | Model Number:standard |

| Production Capacity:as required | Voltage:as required | Power(W):according to the capacity | Weight:according to the capacity |

| Dimension(L*W*H):according to the capacity | Certification:ISO9001:2008 | Warranty:25years | After-sales Service Provided:Overseas service center available |

| Project:design,manufacture,sale and install machines | System:PLC system, etc | Processing Types:wheat/corn/maize | Production standard:Europe standard |

| Quality:Best Design | Equipments:Complete sets or single one/ high-end market | color:white and green | Feature:high efficiency/low cost |

| Flour extraction:72%-90% | Type:grain processing equipment |

Hebei Africa Machinery Co., Ltd

We are the only one manufacturer that produce Europe standard quality flour mill in China. We have 6 branch factories, 2 Roller mill factories, 2 Sifter factories, Cleaning system machine factory and pipes factory to become the largest flour mill supplier in China. And reach world first class standard

passed ISO excellent in quality reasonable in price good aftersales servise

Corn processing plant Corn roller mill

maize flou .

The process of flour milling usually consist of the following:

1.grainstorage (silos, or warehouse)

2. Cleaning system (sifter, destoner, separator, magnet, scourer, etc)

3. Dampening (dampener, conditioning silos, etc)

4. Milling system (roller mill, plan sifter, purifier, impact detacher, etc.)

5. Flour pressure and blending system (if need)

6. Flour packing and stacking

Receiving Section (Pre-cleaning section)

To pre-clean the grain in the receiving to grain storage tank. Clean out some big impurity to protect the discharge outlet not block up when feed to flour mill. Also protect the following equipment working safely .

Cleaning Section.

Further to clean out the middle and small impurity from grain. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on…

Milling

Mill: mill the grain to break the integrity by the roller moving

Sifter: to separate the flour and bran, also separate large size and small size to enssure flour quality.

Packing Section

Our packing machine is fully automatic weighting and packing. The precision is less than 0.2%. Like 25kg/bag, the weight is not less than or no more than 50g.

grainstorage silos

Controlling section -- PLC SYSTEM can be selected

Automatically display raw cereal , clean grain, flour , pollard, bran instant flowing quantity

Siemens or Schneider electrical parts, Omron sensor.

Adopt Japan brand rollers, SKF bearing, good painting, high manufacture accuracy.

all the machine packed in fumigation-free wooden cartons

| Packaging Detail:The products will be packed by the protect film inner, water-repellent plastic outside. The wood packing is necessary If sent by less than a container. The machine will be fixed by steel rope in the container. All the machine packed in fumigation-free wooden cartons.Make sure it is in good condition when arrives destination. |

| Delivery Detail:Within 60 days after receiving advanced payment and L/C |