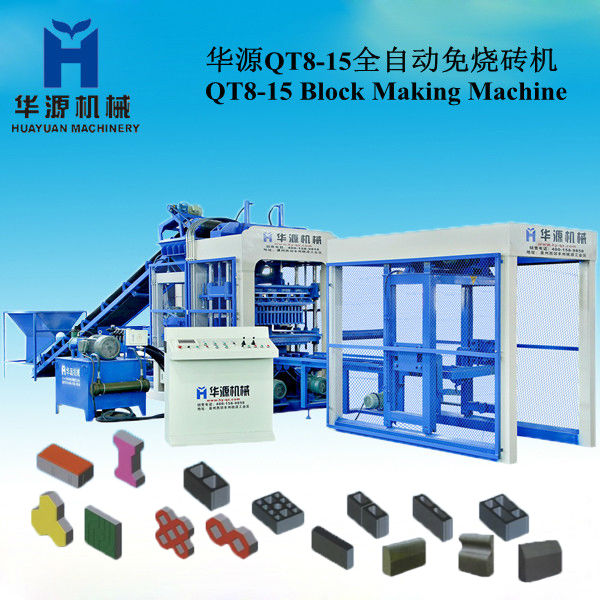

2013 Newly high capacity of fly ash brick making machine QT8-15 fly ash brick making machine in india price

| Condition:New | Type:Hollow Block Making Machine | Brick Raw Material:Concrete | Processing:Brick Production Line |

| Method:Hydraulic Pressure | Automatic:Yes | Capacity:20sets per month | Place of Origin:Fujian China (Mainland) |

| Brand Name:HYM | Model Number:QT8-15 fly ash brick making machine | Voltage:380V | Power:38.1kw |

| Dimension(L*W*H):9800*3600*2800 | Certification:ISO9001:2000 | After-sales Service Provided:Engineers available to service machinery overseas | color:white and blue |

| Cycle Time:15-20(s) | Total Power:38.1(kw) | Vibration Force:85KN | Vibration Frequency:50HZ |

| Pallet Size:900*840*25mm | Vibration Type:hydraulic or moto vibration | Gross Weight:10500(kg) of concrete block machine |

1,block making machine manufacturer in china

2,power:38.1kw

3,pallet:900*840*25mm

4,function:making block machine

ISO&CE&SGS

2013 Newly high capacity of fly ash brick making machine QT8-15 fly ash brick making machine in india price Concrete Brick making machine,brick making machine,concrete brick machine,concrete block making machine,hollow brick machine,hollow brick making machine,brick making machinery.

1,Main technical Specifications:

Oriented column: made of special steel, chrome plated , and can bear powerful suppress and wears well.

Mold head: synchronize with mechanic, electricity and hydraulic. Products made by the same pallet are within narrow degree of errors.

Feeding:Sensor and hydraulic are droved synchronically in proportion, the force to swing material and arch-breaking generates strong centrifugal power to feed materials, which results in rapid feeding and particularly good for thin-walled products with multi-holes.

Vibration:Hydraulic drive and multi-source vibration system, the computer-controlled hydraulic drive generated vertical synchronization. Adjustable frequency makes it possible to feeding in low-frequency. High frequency operation guarantees good effects of different raw materials and the vibration acceleration is up to 17.5.

Control system:Computer control, HMI, electric parts uses brands like Mitsubishi. With experienced production actions, design philosophy integrated international and Chinese trends. To operate it requires small training and no experts. Its strong memory makes it possible to be upgraded.

Store and distribute materials devices: the computer-controlled material supply avoids suppressing materials, and ensures well-distributed feeding and stable and well product intensity.

Raw materials :crushed stone ,sand, cement, etc; many type of industrial waste, like, lime, fly ash, slag, coal gangue, gravel, perlite, ect. .

multiple uses, it can produce all type of standard building blocks by changing mould.

1,Multi-holes block and hollow block .

2,Ceram site heat preservation block.

3,Composite heat preservation concrete block

The above production come with good heat preservation performance, and it meets the new national energy conservation policy.

2,Main technical parameters:

| Cycle Time | 15-20(s) | Total Power | 38.1(kw) |

| Vibration Type | hydraulic vibration | Vibration Force | 85KN |

| Gross Weight | 10500(kg) | Motor Frequency | 50HZ |

| Pallet Size | 900×840×25(mm) | Machine Size | 9800×3600×2800(mm) |

| Rated Pressure | 31.5Mpa | Stacking Power | 2.25kw |

3,The Capacity of QT8-15 fly ash brick making machine

| Bricks | Brick sizes | Production per Mold(pcs) | Production per Shift(8 hours) | Picture |

| Perforated brick | 240x115x90mm | 18 | 25920-34560Pcs | |

| Solid brick | 240x115x51mm | 42 | 60480-80640Pcs | |

| Hollow brick | 390x190x190mm | 8 | 11520-15360Pcs | |

| Color paver | 200x100x60mm | 28 | 31600-40320Pcs |

4,QT8-15 fly ash brick making machine production line

| Warranty: |

| 1. Total warranty/Guarantee: 6 months |

| Shipping | ||

Batching Plant/ JS750 Mixer / Stacking Machine:

Auxiliary Products |

| Payment & Payment terms: | |

|

5,QTY8-15 fly ash brick making machineother information:

1. Area: Workshop area: 150-200m2, all factory area 3000m2, the bigger, the better.

2. Workers : three or four.

3. Ratio of raw material:cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

4.hollow block weight::

(400*200*200) :17KG,(400*150*200):13.5KG,(400*100*200):10KG

5. raw material consumption per day:220-230T

6. water consumption per day:3%-5% of raw material .Weight.

6,Workshop and Products Shows:

7, Recommend products:

8,Our world Clients:

9,Pls don`t hesitate to contact me:

| Packaging Detail:1,High automatic and easy to operate2,concrete block machine3,concrete block making machine4,fly ash brick making machine with standard seaworth packing |

| Delivery Detail:30 working days |