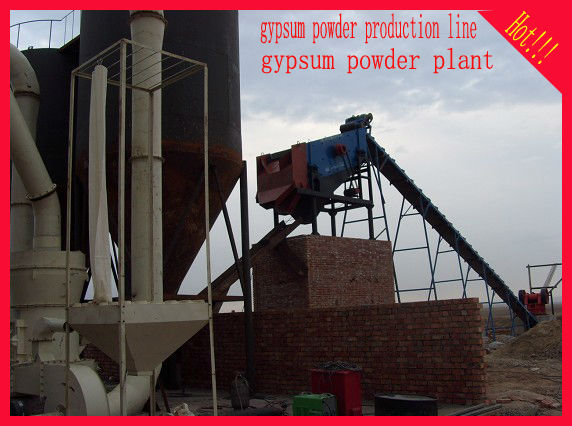

2013 New sytle Natural Glypsum powder production line from wanqi

| Condition:New | Application:gypsum powder production line | Automatic Grade:Automatic | Production Capacity:20000--30000 ton /year |

| Place of Origin:Henan China (Mainland) | Brand Name:Wanqi | Model Number:gypsum powder production line | Voltage:380V 440V |

| Power(W):gypsum powder production line | Features:full automatic | Certification:CE ISO | Warranty:1 year,1year |

| After-sales Service Provided:Engineers available to service machinery overseas | Production Capacity::99% | crushing:jaw crusher/ hammer crusher | Style::Calciner |

| Fuel::Coal, natural gas, heavy oil or light oil | Working time::Continous | Raw material::Gypsum rock or phosphogypsum | usage of product::construction usage/ building gypsum powder |

| technology::vertical popper/ thermal oil furnace/ rotary calciner | Drying type:Boiling furnace |

2013 New sytle Natural Glypsum powder production line from wanqi

| Instruction; |

| Gypsum, one of the five gel materials, plays an important role in the national economy. It is widely used in construction, building materials, industrial molds and art models, chemical industry and agriculture, food processing and pharmaceutical cosmetic and many other industries, which is an quite important industrial raw material. Currently, both gypsum powder production technology and production line automation level are not high, probably in the manual or semi-automatic condition. Therefore, gypsum powder product has been in a low-level, low-quality state for a period of time. Gypsum powder production line (all-natural gypsum) adopts advanced procedure and equipments like vertical mill, ball mill and so on, of which ball mill may be the most broadly utilized calcining equipment at present in China using the positive aspects of tiny size, fine creating capacity, easy structure, little occupied places,low energy consumption, handy operation, automatic control, great excellent, best phase composition,steady physical overall performance and low investment, and so forth..It is widely used into calcining process of allnatural gypsum and chemical gypsum and has been sold to Thailand, Uzbekistan, Columbia, Mexico and so on. |

| Gypsum Powder Production Line Equipments |

| Actually, mechanized production lines of building plaster basically share the same process. The production process can be summarized as crushing system, roasting system and grinding aging system. Equipments can be used in the crushing system: jaw crusher, roll crusher, impact crusher, self-impact crusher, hammer crusher, etc.. Different types of rotary kilns can be choosed in the calcined(roasting) system according to the specifications of the material. Besides, calcining process can be divided into two kinds: burning the first, grinding second; grinding the first, burning second. Drying equipments: stove or/and dryer. Grinding equipments: raymond mill, vertical mill, cone grinding machine,etc.. |

Main Parts of Equipment: | |

| 1. Ore Station | 2. Crusher |

| 3. Grinding System | 4. Calcine Kiln |

| 5. Exit System | 6. Material Elevator |

| 7. Silo | 8. Entrance System |

| 9. Coal/Natural Gas System | 10. Dust Collector |

| 11. Material Elevator | 12. Aging Silo |

| Packaging Detail:containers.bulk packing,Containers No.depends on annual capacity |

| Delivery Detail:35days |