2013 hot sales tower type grain dryer machine with 10% discount

| Condition:New | Type:Hot Air Furnace | Place of Origin:Henan China (Mainland) | Brand Name:Superior |

| Model Number:S6709 | Voltage:Accorting to your demands | Power(W):Accorting to your demands | Dimension(L*W*H):Accorting to your capacity |

| Weight:Accorting to your capacity | Certification:ISO | Warranty:3 YEARS,for using time | After-sales Service Provided:Engineers available to service machinery overseas |

| Grain Dryer Suitable Materials:Rice, Wheat, Corn, Soybean, Paddy | color:as you want | maintain:easy and convinient | Temperature:50-60centigrade |

Outdoor dryer can reduce building cost

High moisture paddy or wheat can be dried easily

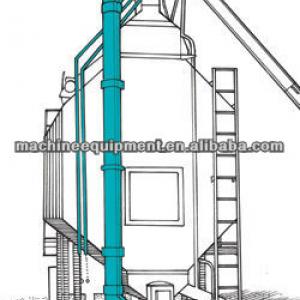

Introduced the latest advanced technology from Japan, large outdoor hypothermic circulatory grain dryer

1.Outdoor dryer can reduce building cost

The outdoor dryer needn’t build a drying room, small area occupation, shorten the installation period, reduce the cost of the whole equipment; they are very helpful to achieve profitable operations.

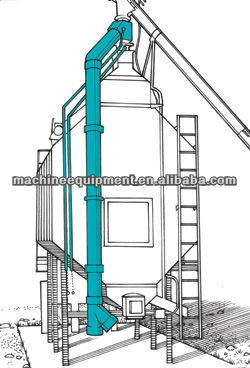

2. High moisture paddy or wheat can be dried easily

The internal distribution of “Z” shape “hill-shaped multi-tube structure” can circulate mixing grain perfectly, prevent drying inhomogeneous, crackle, over drying etc, high moisture paddy or wheat can be dried easily and the quality can be guaranteed after drying by low temperatures, high winds, comprehensive ventilation structure.

3. Installation working hours can be reduced bysemi-products delivery

Many parts have been assembled before delivery, it can reduce installation working hours, reduce the time limit from project and costs on site.In addition, wires and pipe work, wiring material, and the air pipe etc are also carried out simultaneously, when the completion installation of the mechanical parts, they can also be finished together at the same time.

4. Hot-blast stovefor drying, reduce costs and improve quality

Hot-blast stove uses coal, wood or rice husk as fuel, it can reduce drying costssignificantly, and computer control can be simplified management operations.

Model | CGD-25 | CGD-28 | CGD30 | ||

Capacity | Paddy | 2020-2500Kgs | 2020-2800Kgs | 2020-3000Kgs | |

(1 liter=560g) | |||||

Wheat | 2460-2700Kgs | 2460-3000Kgs | 2460-3200Kgs | ||

(1 liter=680g) | |||||

Dimension mm (L×W×H) | 2300×9865×16741 | 2300×9865×17941 | 2300×9865×19141 | ||

Dry Style | Hot-blast Stove | ||||

Fuel | Coal, Wood, Rice husk | ||||

Function | Paddy inlet /outlet | 30t/h | 30t/h | 30t/h | |

| Wheat inlet/outlet | 30t/h | 30t/h | 30t/h | ||

Water Reduction Rate per Hour | Paddy | 0.5-0.8%h | |||

| Wheat | 0.7-1.0%h | ||||

Above list of reduction water rate is for reference only, the actual numerical depends on ambient temperature, relative temperature, drying materials, hot air temperature anddifference water content from before and after among drying.

| Packaging Detail:For Steel Silos: Bracket, tray and fully sheathed case act as the main packaging containers for storage equipments,shipped in 20ft or 40ft containers. Bracket and pallet are as the packaging container for side panels, reinforcing rib and vane. Goods like trestle stand, roof are packed with simple steel power (similar to bundle packaging), directly shippable. Construction materials such as bolts, welding rod are containerized with closed wooden box. |

| Delivery Detail:30 working dats after receiving you deposiy |