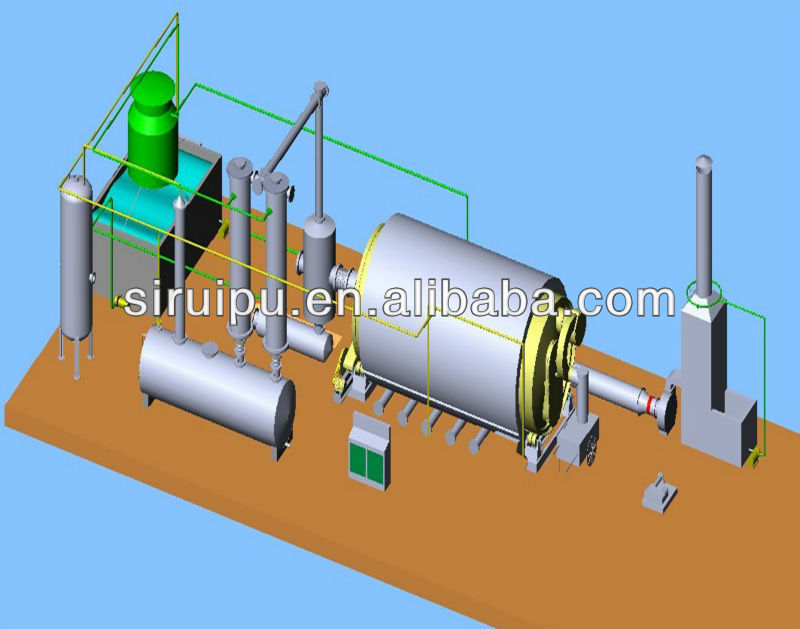

2013 hot sale used tyre plastic rubber recycling machine to oil

| Place of Origin:Henan China (Mainland) | Brand Name:sriple | Model Number:SRP-2800*6000 | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas | steel:national standard boiler plate Q345R boiler plate | color:customised | function:waste tyre plastic rubber to fuel oil and petrol and diesel |

| handling capacity:customised | Certification:ISO/CE/SGS/BV | Condition:New |

Specifications

1.waste tire recycling to oil and carbon black

2.no pollution to air,water

3.45%-50% oil rate

4. save energy and labour

Product features

1. Unique design of reactor guarantee the service life and safety.

2. No need to crush tires. We can feed whole tires into the reactor. Save manpower and increase efficiency.

3. Electric cabinet help you watch the temperature and easy to control power.

4. Technical condensers and circulating water guarantee the cooling effect and improve oil yield.

5. The residual gas (tail gas) recycle to furnace as fuel. Save energy.

6. Flue gas is processed by dust removal device. Reach the emission standard.

7. Experienced engineers will help you install the machine and train your workers.

Advantages:

1> Security:

A: Adopting automatic submerged welding-arc technology

B:All of the weldings will be detected by the ultrasonic nondestructive testing method .

C:Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.

D:anti explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system

2> Environmental-friendly:

A:Emission Standard: Adopting special gas scrubbers

B:Smell during operation: Fully enclosed during the operation

C :Water pollution: During the operation, the water we use is recycling one to cool down the

gas-oil and convert into liquid oil in the condensers. No pollution at all.

D:Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be

deep-processed or sold directly with its value.

3> Full open door design: Speedy Loading in and steel-drawing out, easily cooling down after one batch finished, saving time; No leaking with special high temperature flexible

Graphite packing.

3> Fully enclosed Carbon black discharging system under high temperature

4> Energy conservation and low cost on operation

AFTER SALES SERVICE:

1.Quality warranty period: One year warranty for the main reactor of pyrolysis machines and lifetime maintenance for complete set of machines.

2.Our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.

Approx oil yield of different raw materials

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| Leftovers of paper | Wet 15-20%, dry 60% |

| House garbage | 35-50% |

| Plastic cable | 80% |

| Plastic bag | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Sole | 30% |

| Big tires | 45-50% |

| Small tires | 35-40% |

| PVC | Not suitable |

| PET | Not suitable |

| Packaging Detail:1*40FR+1*40HQ for 10 tons2*40HQ for 6tons |

| Delivery Detail:15 days |