2013 Hot Sale ore grinding Ball Mill manufacture

| Condition:New | Type:Ball Mill | Motor Type:AC Motor | Power(W):20-1500 |

| Capacity(t/h):1.8-78 | Place of Origin:Henan China (Mainland) | Brand Name:ZK | Model Number:MQZ |

| Dimension(L*W*H):Dia0.9-3.6m | Weight:2-500t | Certification:ISO9001/ISO14000,ISO9001:14000 | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Design:offer | Installation:under our engineer's guide | Ttesting:we offer |

| After sale service:for the whole using life | Cylinder rev(r/min):18.3-38 | Driving Type:edge and center drive | Material::Q235 |

| Name:ball mill manufacture |

ore grinding Ball Mill manufacture

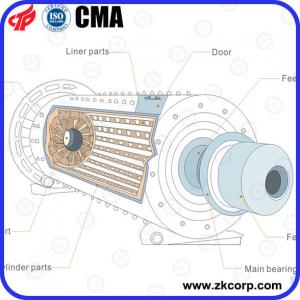

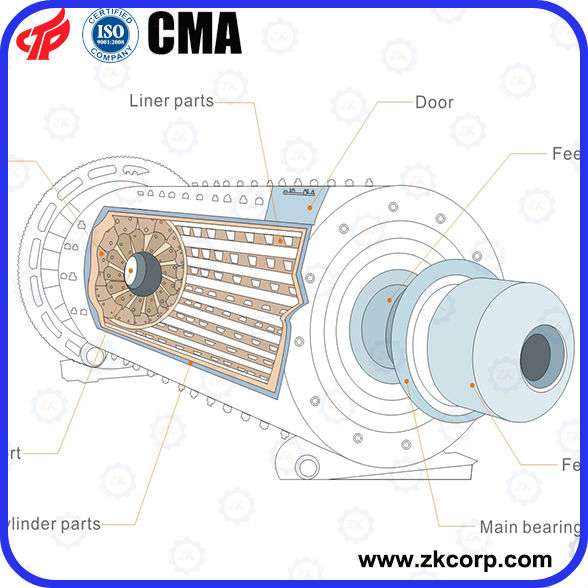

Ore grinding Ball mill structure: Contained feeding system, the discharhing system, the transmission system(speed reducer, small transmission gear, electrical machinery, electric control) & etc.

Bll mill structure

How to choose the suitable Ball Mill ?

Notes on choosing the type of ball mill:

1. Know the hardness of your own ore.

2. Choose the energy-saving ball mill to the great extent.

3. Know the ore fineness required.

4. Choose the right diameter and length of the ball mill according to the output requ irement.

5. Buy it from the professional ball mill manufacturer relative to your ore which would be best.

6. The manufacturer should hold the market share in the place where your enterprise located.

7. Choose the new-type transformation ball mill with the rotate speed different from the module.

8. Choose the aperture of the close board and the sub-freignt space according to the ore fineness of your demand.

9. Choose the lining board material and set the thickness of the steel plate on the mill body by the price of the ball mill.

10. Slect themodules of the big gear and pinion, and the manufacturers of the electric motor and the speed

reducer.

Main parameters of the ball mill

model | cylinder rev (r/min) | Ball quantity (t) | feeding size(mm) | Discharge size(mm) | output(t/h) | motor | |

| model | power | ||||||

| MQG900X1800 | 38 | 1.8 | ≤ 25 | 0.074-.06 | 0.8-1 | Y255M-8 | 22 |

| MQG900X3000 | 37.4 | 2.7 | ≤25 | 0.074-0.3 | 0.8 | Y225M-6 | 30 |

| MQG1200x2400 | 32 | 4.8 | ≤25 | 0.074-.06 | 1.5-2 | Y280M-8 | 45 |

| MQG1200X4500 | 30 | 5.2 | ≤25 | 0.074-.06 | 1.5 | Y280M-6 | 55 |

| MQG1500x4500 | 28.8 | 10 | ≤25 | 0.074-0.4 | 3-4 | JR126-8 | 110 |

| MQG1500x5700 | 28.8 | 12 | ≤25 | 0.074-0.4 | 3-5 | JR127-8 | 130 |

| MQG1500x6400 | 28.8 | 13 | ≤25 | 0.074-0.4 | 3-5 | JR127-8 | 130 |

| MQG1830x5400 | 24.5 | 15 | ≤25 | 0.074-0.4 | 5-7 | JR137-8 | 210 |

| MQG18306400 | 24.5 | 19 | ≤25 | 0.074-0.4 | 5-7 | JR137-8 | 210 |

| MQG1830x7000 | 24.5 | 20 | ≤25 | 0.074-0.4 | 6-8 | JR138-8 | 245 |

| MQG2200x7000 | 21.6 | 30 | ≤25 | 0.074-0.8 | 8-10 | JR158-8 | 380 |

| MQG2200x9000 | 21.4 | 34 | ≤25 | 0.074-0.8 | 8-10 | JR1510-8 | 475 |

| MQG2400x7000 | 20.4 | 36 | ≤25 | 0.074-0.8 | 10-14 | JR1510-8 | 475 |

| MQG2400x8000 | 20.4 | 42 | ≤25 | 0.074-0.8 | 10-14 | YR630-8 | 560 |

| MQG2600x8000 | 19.6 | 52 | ≤25 | 0.074-0.8 | 16-20 | JR1512-8 | 630 |

| MQG3000x9000 | 18.3 | 78 | ≤25 | 0.074-0.8 | 20-25 | YR1000-8/1180 | 1000 |

Ball mill Installation

| Packaging Detail:Sea worthy packing for ore grinding Ball Mill manufacture |

| Delivery Detail:50 days |