AAC block making machine in China

Henan HUAYI Machinery is a professional manufacturer of autoclave for AAC block machine, AAC block is one of new construction materials. It is light-weight, environmental-protection, good thermal and sound insulation proverty and incombustibility.

Our machine can produce all the size AAC block you wanted with different moulds.

We have our own sale team and factory.

Welcome to visit our company.

1.The description of AAC Block

Areated concrete brick (light brick ) is the light and porous buidling material. It has light keeping temperature cant burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Common concrete density is usually 1600-2400kg/m3,but Areated concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain,main use silicon material (for example:coal ash,sand,stone dust and others ),through making the material small for example sand,they can be used directly if has enough degree of small (for example coal ash.Mixing calcium material lime cement water to a special slop,then add the aluminum dust and the additive.Make the aluminum dust and the special slop have a Chemical reflect.then produce Hydrogen to make the concrete slop to expanding or swell,foam.Next,put them into the curing room to concreting cutting steaming curing,last,there will bacome the light brick,the porous rate is 70-80%.

2.Process of production line

Materials → Calculate→ Mixing with water →Putting Mould→ Casting → Pre-curing→De-moulding → Cutting → Separating → Autoclaving→ Unloading → Packing

1).Raw material preparation and storage

(equipment: jaw crusher,Bucket elevator ,silo,Electronic Vibrating Feeder,Ball Mill ,mould and so on ) Fly ash (or sand, stone) by electromagnetic vibrating feeder and belt into the ball mill, the fly ash( after grinding fine sand, stone) with fly ash pump were sent to the pulp cans of storage. Lime by electromagnetic vibrating feeder and belt into the jaw crusher are broken, broken by dou type of lime hoist into lime storage and then by screw conveyor into fine after grinding ball mill, material is screw conveyor, dou type hoist into powder batching.

Chemicals in a certain proportion after artificial measurement, made certain density solutions, into in the tank is stored. Aluminium by aluminum library shipped to the production workshop, electric hoist ascent to ingredients floor on the second floor combine ingredients in blender filled quantitative water, stir into aluminum powder suspending liquid.

2).Ingredients, mixing, pouring

(equipment: screw conveyer,silo,Aluminum mixer,Pouring machine,control system and so on) Fly ash slurry or sand slurry will be measured by slurry electronic measurement in ingredients center.Lime, cement are sent by spiral feeder to measure.Then all the raw materials will be sent to pouring mixer machine by feeding equipment for high-speed mixing,All measurement through PLC automatic centralized control,to assure accuracy and continuity of measurement.After a few minutes,then the arm ofcasting machinestarts pouring material to themold box.

3).Static stop maintenance

(equipment:Static stop maintenance room)

After pouring,mould should be sent to static stop maintenance room for preliminary condensation, the temperature need 50 to 70°C for 1.5-2 hours.(according to the geographical advantages, can discharge the process).

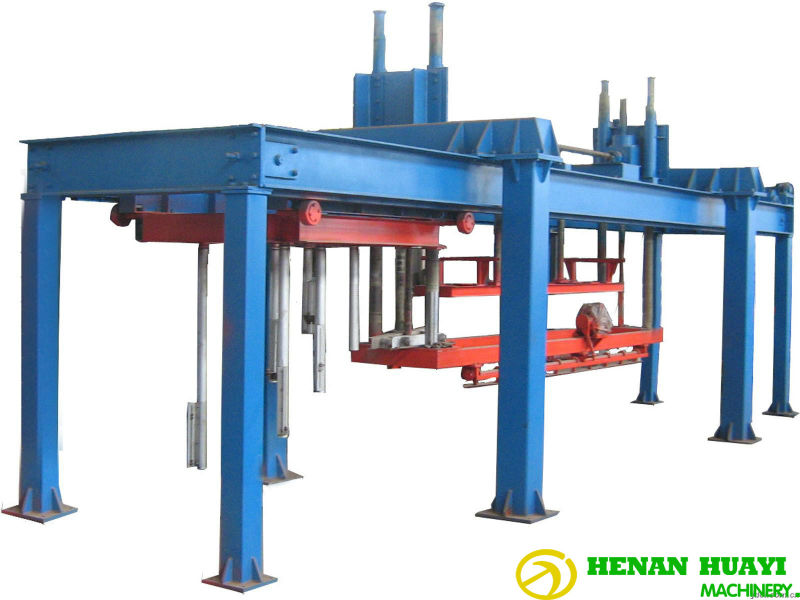

4).Cutting section

(equipment: aac cutting machine,air compressor,Recycling mixer)

AAC blocks Cutting :Turns over the hoisting mechanisms airborne to turn over together the mold belt body on 90 degree laying aside cutting car, the drawing of patterns keeps the body together with the side bar cuts on the car, cutting car to make the power by the electrical machinery to walk, completes longitudinal cutting, the milling, level cutting through the slitting installment; Cutting car continues to walk after the infeed set-up central location stop, the infeed set-up starts, transverse cutting vertical undercuts from the top downward completes the across cutting; Cutting car to walk again to the grouping hoisting mechanisms place (side bar hangs continually) by the grouping hoisting mechanisms the body to steams raises on the car, cutting car to return to the initial position to carry on the next cutting circulation.

Stripping the given photo-cell and lateral plate stay together with cars, Cutting edge horn produce given photo-cell and waste, the screw conveyor to cutting waste pulp by stirring loops made waste water machine, the slurry, stay ingredients when used.

The parameters Autoclaved Concrete cutting machine are as follows:

| Number | size | Rough Before Cutting(mm) | Cutting Cycle | Cutting Ability(m3/yr) | Cutting Precision | Total Power(kw) | Dimension(mm) |

| 1 | 4.2m | 4250*1240*650 | 6-8min/block | Above 100,000 | <=3.1.1mm | 25.5 | 12200*4200*5600 |

| 2 | 4.8m | 4860*1560*650 | 6-8min/block | Above 200,000 | <=3.1.1mm | 30 | 16000*6000*5500 |

| 3 | 6m | 6050*1540*650 | 6-8min/block | Above 200,000 | <=3.1.1mm | 30 | 18500*6000*5800 |

5).Coding andautoclave

(equipment: steaming larry,windlass,autoclaves,boiler and so on)

Finished groupingsteaming larrywill be sent to autoclaves by the slowly windlass,after 8-10hours blocks in autoclaves ,the finished blocks will be take out with the windlass behind the autoclave. A semi-finished crane hoist will send the blocks with side panel to conveying groove,then the the blocks would be sent to wooden pallets in the packing line by a finished crance hoist. The worker or automatic packing machine will pack the blocks ,the they are in finished goods yard. The empty side panel return and go on its cycle after cleaning.

6).Finished autoclaved concrete block:

3.Huayi Offering AAC Block Cutting Machine with Following Annual Capacity:

50,000 m3AAC Block Cutting Machine; 60,000 m3AAC Block Cutting Machine;

100,000 m3AAC Block Cutting Machine; 150,000 m3AAC Block Cutting Machine;

200,000 m3AAC Block Cutting Machine; 250,000 m3AAC Block Cutting Machine;

300,000 m3AAC Block Cutting Machine; 350,000 m3AAC Block Cutting Machine;

400,000 m3AAC Block Cutting Machine; 450,000 m3AAC Block Cutting Machine;

Welcome to visit our factory in Wenxian,Henan,the birthplace of Taijiquan!