2012 newest type Seaweed drier machine with high quality

| Type:Vacuum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:qiangyuan | Model Number:varies |

| condition:new |

Seaweed drier machine

1.Reasonable design.

2.High efficiency.

3.Low energy consumption.

4.Easy to maintain and easy to operate.

Characteristics:

(1) Environment-protecting and energy-reducing.

(3) Reliable, simple operation, convenient maintenance, safe and durable.

(4) Meet the material widely.

(5) Ensure the quality of lignite change.

(6) Continuous work, large capacity.

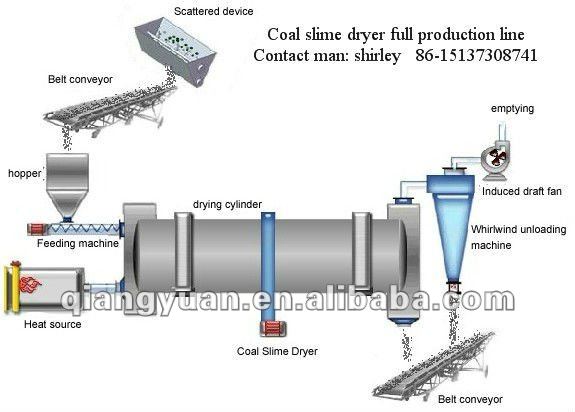

Working principle:

The first drying area is in the high humidity status ,removing most of moisture by 400 °C to make sure the chemical composition of the rawmaterial no change and not easy to burn .The temperature of the second area is 300°C, removing the moisture by middle enduring air temperature to ensure the rawmaterial no coking.The temperature of the third area is 120°C-210°C,using the crushing device in the rotary body ,repeating crushing, scattering the material by down-flow drying .The forth drying area is high exhausting area , the temperature is 60°C-80°C,removing moisture by low temperature and hot air that produced by the inducing air system .Linkman: shirley Sk: shirley200986 or +86-15137308741

Descriptions:

Wet material is loaded from one head of the drying Equipment, and then it is stirred by the bafflers that is uniformly distributed in the barrel. Material is uniformly distributed and dispersed in the dryer, fully contact the hot air of parallel (or counter) flow, so the drying process is expedited, and the impulsion power of media transfer is enhanced. During the drying process, material is under the effect of angled baffler and hot air, moves to the star shape unloader that is at the other head of the driver. Sk id: shirley200986 or Mobile: +86-15137308741

Applications:

Applicable for drying big particles, heavy particles in chemical, mining, and metallurgy, such as mining area, cinder of blast furnace, coal, powder of metal, phosphate fertilizer and thiamine.

For drying the powder or particles with special requirements, such as HP foaming blowing agent, residule of alcohol, light calcium carbonate, active clay, magnetic powder, graphite, and residue of medicine. For materials to be dried under low temperature and large lot continuous production. Sk id: shirley200986 or Mobile: +86-15137308741

Features:

The motorization level of the barrel is high, and the production capacity is high.

The resistance that the material passes through the barrel is less, and the power consumption is low.

Application capability to different characters of materials is high.

The operation is stable, the operation fee is low, and the uniformity of product drying is good.Linkman: shirley Sk: shirley200986 or +86-15137308741

| Packaging Detail:standard container ( at your option ) |

| Delivery Detail:3-20 days after receiving downpayment of as your request |