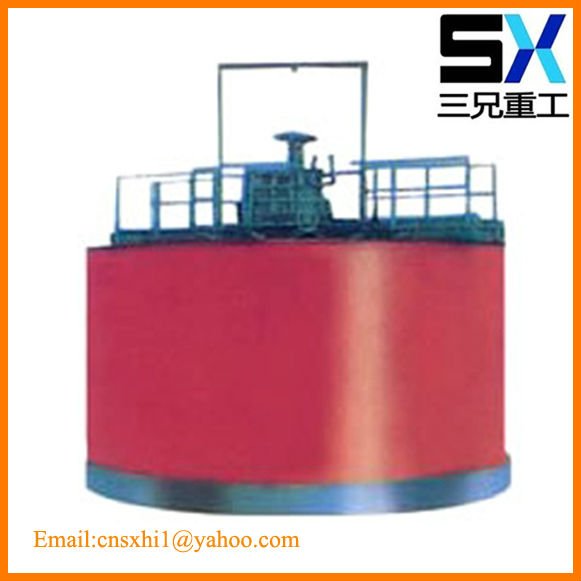

2012 Hot Selling High Capacity Thickener

| Place of Origin:Henan China (Mainland) | Brand Name:SX | Model Number:NZS Series | After-sales Service Provided:Engineers available to service machinery overseas |

| Certificate:ISO 9001:2000 | Installation:Our engineer guiding | Color:According to your demand | Guarantee:1 year |

High Capacity Thickener overview

High Capacity Thickeners are not only sedimentation equipments but also new type dehydrating equipments with the mash percolate features. By adding flocculating agent, bigger the diameter of the deposit solid grain, speed up the deposit. The High Capacity Thickener is usually used after floatation separator when it is applied in beneficiation process.

High Capacity Thickeners Application

High Capacity Thickeners are widely used for melting, chemical, coal, non metal concentration, environment protected etc industry. The High Capacity Thickener machine of our company is suitable for dehydrating water of the concentration and gangue in the concentrating factory, make the mash of 20-30% raise up to 40-70% about. The High Capacity Thickener is usually used after floatation separator when it is applied in beneficiation process.

High Capacity Thickenersworking principle

Slurry enters chute through ore tank firstly, and then separating zone by waterpower. Mineral with strong magnetism is absorbed on the barrel surface, sent to concentrate discharging zone and discharged into concentrate box by water effect Gangue and ore with weak magnetism are discharged into a pipe in opposite direction of barrel.

High Capacity Thickenersproject

High Capacity Thickeners related production line,Coal preparation plant, aluminum processing plant, antimony ore Concentrator, copper ore Concentrator, gold ore processing plant, and so on.

High Capacity Thickener is a concentrator plant which is designed to dehydrate the ore concentration and tailings. High Capacity Thickener is widely used in chemical, construct, metallurgy, machine making, food, food processing, feed processing, environmental protection and ceramics.

High Capacity Thickenersfeatures

1. Adding flocculating agent to enlarge the diameter of the deposit solid grain, speed up the deposit.

2. Set the lean board, reduce the mash deposit distance, and increase the deposit area.

3. Have effect on flocculating. Percolating, compressing and dealing quantity of the slurry deposits.

4. Stable running conditions.

5. Equipped with the perfect automatic facility.

Main Technical Parameters

| Model | Drive fashion | Concentrate Diameter(mm) | Concentrate Depth(m) | Capacity (t/24h) | Motor Model | Motor Power(kw) | Size (lxwxh)mm |

| NZS-1 | center drive | 1.8 | 1.8 | 5.6 | Y90L-6 | 1.1 | 2000X1960X2900 |

| NZS-3 | center drive | 3.6 | 1.8 | 22.4 | Y90L-6 | 1.1 | 3917X3787X3190 |

| NZS-6 | center drive | 6 | 3 | 62 | Y100L2-4 | 3 | 6170X6170X5053 |

| NZS-9 | center drive | 9 | 3 | 140 | Y132S-6 | 3 | 10000X10000X5337 |

| NZS-12 | center drive | 12 | 3.5 | 250 | Y132S-6 | 3 | 15500X12000X6625 |

| NZS-15 | roll around | 15 | 3.5 | 390 | Y132S-4 | 5.5 | 16545X15670X7017 |

| NZS-18 | roll around | 18 | 3.5 | 560 | Y132S-4 | 5.5 | 19742X18864X7047 |

| NZS-15 | aroud the rack | 15 | 3.5 | 390 | Y132S-4 | 5.5 | 17000X15000X7000 |

| NZS-18 | aroud the rack | 18 | 3.5 | 560 | Y132S-4 | 5.5 | 20000X18000X7000 |

If you have any need, please feel free to contact us!

| Packaging Detail:Container or In Bulk |

| Delivery Detail:30 days after deposit or to be discussed |