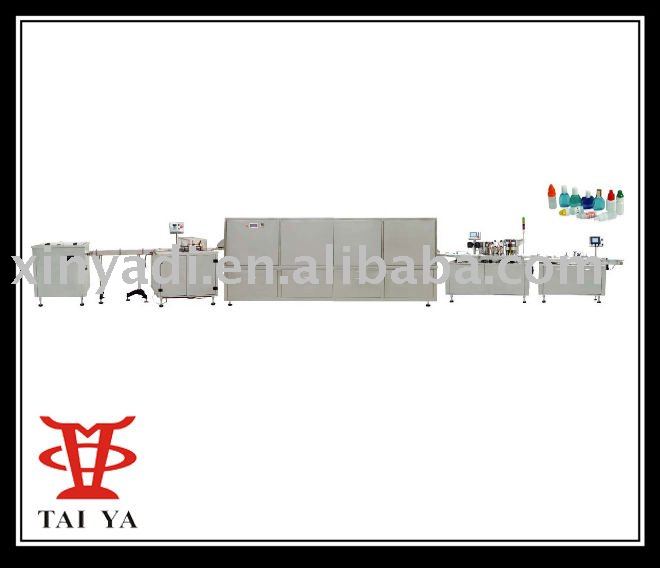

2011 eyedrop(nasal drop) washing,filling, plugging,capping, and labeling production line in pharamaceutical

| Condition:New | Application:Medical | Driven Type:Mechanical | Automatic Grade:Automatic |

| Power:6KW | Packaging Type:Bottles | Packaging Material:Plastic | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:xinyadi | Model Number:YGX-Y | Applicable:eye drop in pharmaceutical | Type:Filling Machine,Capping Machine |

YGX-Y Series Eyedrop(nasal drop) Washing, Drying, Filling,Plugging, capping, Labeling complete production line for pharmaceuticThis line includes:

LP-100 Auto Bottle -Arranging Machine;

GTX Drum-Type Bottle-Washing Machine;

CMG Tunnel-type Ozone Sterilizing and Drying Machine;

YGX eyedrop filling,plugging and capping Machine;

GLT-A/B(vertical) Auto High-speed Labeling Machine.

_____________________________________________________________________

Application:

The line is suitable for various sizes and shapes of eyedrop(nasal drop) bottles in arranging, washing, drying, filling & plugging&capping, labeling.

Main Technical Parameters

Filling volume: 2-50ml

Filling precision: ≤±1.5%

Water consumption: 500L/H

Water pressure: 0.25Mpa

Clean compressed air consumption: 300L/min.

Clean compressed air pressure: 0.15-0.25Mpa

Power supply: 220V 50HZ

Power: 6KW

Overall dimension(LXWXH): 9000x1400x1900mm

Production capacity: 80-120 bottles/min.

_____________________________________________________________________

Features of the line:

Combined with the latest advanced technology and our reasonable structure design, this line has many advantages including: high automalization, stable running system, accurate filling, and high efficiency. The YGX-Y effectively integrates the mechanical and electrical technology. It meets the GMP Standard.

The LP-100 Auto Arranging Machine is equipped with a curving mechanical overturn device which can arrange the bottles in a quick and orderly manner. It contains an advanced overload safety device, requires no air-pump, and uses less energy. The LP-100 is both quiet and easy to operate. Its highly efficient auto-arranging capability makes the LP-100 a stable performer.

The GTX Rotary Washing Machine utilizes a unique structural design by adapting a polygonal roller to rotate intermittently, which makes it very easy to clean. The GTX is conveniently simple to operate and requires low water consumption and maintenance.

The CMG Tunnel-type Drying and Sterilizing Machine uses an auto-control and display for the heating system and ozone generator. Its perfect 100-class laminar flow prevents air from entering and ensures complete sterilization under the 100-class environment. Other characteristics of the CMG include: a stable running system, a simple operation, and easy repair-and- maintenance.

The YGX Filling Machine contains an adaptable auto-setting for the filling volume of the peristaltic pump. Screw-capping is torque-fixed and its cylindrical presses do not touch any part of the bottle. The YGX will not operate if it detects an empty bottle, or no plug. Its combined advantages of stable performance, accurate filling, no leakage, and high precision screw capping make the YGX a great machine!

he GLT-A/B Labeling Machine is equipped with a hot-iron printer which is used to finish the label application process. The GLT-A/B can also be used for printing batch numbers and quantity records. It has an auto-display counter and its print format can be easily adjusted, as you so desire.

| Packaging Detail:Wooden box |

| Delivery Detail:40-50 working days after receipt of required samples |