(200TPD) Chromite ore beneficiation plant_gravity separation

| Condition:New | Type:Flotation Separator | Place of Origin:Henan China (Mainland) | Brand Name:GHM |

| Model Number:SF-1.2 | Certificate:ISO9001-2008 | Technical service:avaialble | Installation:guide by engineer |

| Guaranttee:whole using life | spare parts:available |

(200TPD) Chromite ore beneficiation plant_gravity separation

Chromite ore Overview:

Chromiteis an iron chromium oxide: FeCr2O4. It is an oxide mineral belonging to the spinel group. Magnesium can substitute for iron in variable amounts as it forms a solid solution with magnesiochromite (MgCr2O4);[5]substitution of aluminium occurs leading to hercynite (FeAl2O4).[6]

Chrome oreis applied in metallurgical industry, and secondly for the refractory and chemical industries. In metallurgical industry, it needs about one third of the total volume of chromite ore. Besides, the output of steel is proportion to the chromite ore consumption which is about 1%.

Chromite ore beneficiation plant:

Usually, gravity separation process is adopt for chromite ore beneficiation plant.

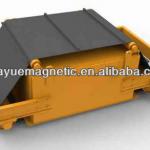

Common equipment used for Chromite ore beneficiation plant

Equipment commonly used for copper ore processing includes: jaw crusher, fine crusher, ball mill, electronic feeder, spiral classifier, spiral chute.

The models for each machine is based on production capacity.

Project case (just for reference):

GHMthanks to our specialists in Sales, Technical, Engineering and Production Departments, each customer can benefit and enjoy our all- around professional supports on plant designing, equipment manufacturing, installation, commissioning, technical training and after- sales service. Welcome to “Good Heavy Machine”!

| Packaging Detail:Standard export package suitable for long distance sea transportation. |

| Delivery Detail:35-40 days after in receipt of deposit |