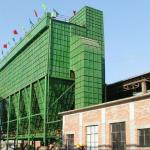

20000-25000 m3/h dust removal equipment

20000-25000 m3/h dust removal equipment, 1.High and low consumption blowing device;, 2 good quality, 3.Electrostatic prec - details see: https://www.machineto.com/20000-25000-m3-h-dust-removal-equipment-10225908

| Type:industrial electrostatic precipitator | Minimum Particle Size:30mg/Nm3 | Place of Origin:China (Mainland) | Brand Name:mayastar |

| Model Number:all |

industrial electrostatic precipitator

FX cyclone dust collector

FX cyclone dust collector is widely used in the dust removal equipment. It is use centrifugal force produced when the gas containing going into the cyclone dust along the tangential direction, let the dust separated from the gas.

It has the advantages of simple structure, low cost, convenient maintenance, high temperature and high pressure resistant, suitable for high dust concentration, dust collection efficiency can reach 99.5% above.

It can be used for collecting dust with particle size smaller than 100um,Large Waste gas processing capacity, small resistance, applicable to waste gas dust removal of the cement factory grinding, drying machine, broken machines and other processing equipment, and it can also be used for dust removal of food, metallurgical and other industries.

Structure and working principle.

FX type dust collector is consist of outer cone, inner cone, sleeve, first class wind inlet, second class wind inlet, ash hopper, discharging pipe, and exhaust tube.

Work Principle: the dust containing gas entering at high speed (more than 12m/s) along the tangent direction of first class wind inlet, Airflow turn the linear motion into circular motion, and at the same time, divided into upper and lower two shares of swirl, upward swirl flow is blocked by the top cover of the dust collector and returned back, downward swirl flow formed top-down intense helical motion between the outer cylinder and sleeve, and generated the centrifugal force, separated the dust from the air, under the centrifugal force the dust throw against the tube wall and rotate along the cylinder wall and deposit into the lower ash bucket of the dust collector, as blocked in the ash hopper the gas purificated at first time change the direction and formed upper and lower inner vortex between the sleeve and the inner cone, and this airflow enter into the second stage air inlet at high speed (more than 24m/s) and formed top to bottom outer vortex inside the cone body. The fine particles not collected at first time separated from the gas under the action of higher centrifugal force and discharged from the along the discharging tube along with inner cone cylinder wall, Outer vortex blocked in inner cone bottom and turn to internal rotation and discharged through the exhaust out of the dust collector.

Main parameters:

Project | FX11A-4 | FX11A-6 |

Purification capacity | 12000-20000 m3/h | 20000-25000 m3/h |

Pressure loss | 88mm H2O | |

Dimensions(L×W×H) | 3500×3400×6524mm | 4700×4200×6534mm |

WEIGHT | 8800KG | 11500KG |

Efficiency | >98.5% | |

MATCHED FAN(for reference) | Y5-48N.8C | Y5-48N.10C |

Power | 22Kw | 37kw |

Spindle speed | 1400rpm | |

| Packaging Detail:standard export packing |

| Delivery Detail:10 days |