1t/h Charcoal Powder Briquetting Plants Hot Sale In Middle East

| Type:Briquette Machines,roller type | Condition:New | Production Capacity:100 sets for per month | Motor Type:AC Motor |

| Power(W):3 phases, 380v, 50hz | Place of Origin:Henan China (Mainland) | Brand Name:E.P | Model Number:HSYQ-750 |

| Dimension(L*W*H):3*2.8*2.5 | Certification:ISO9001& CE,CE | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas |

| capacity:8-9t/h | power:110kw | package:playwood case | raw material:coal, charcoal, lime powder, corn powder, etc. |

| port:Qingdao, Shanghai, Tianjing etc. | roller material:chromium-molybdenum steel |

1t/h Charcoal Powder Briquetting Plants Hot Sale In Middle East

brief introduction:

We havethree kinds of roller type brqiuette extruder, detailed information as following:

1.mechanical pressure briquette machine,which suitable for coal, charcoal, brown coal/lignite, iron power, limestone powder, etc. The largest pressure can up to 40ton. Material of the roller is 65Mn, which belongs to one kind of durable material.

2.hydraulic pressure briquette machine, which matched one hydraulic system and make sure give more pressure to the roller. The largest pressure can up to 600Tons. Which mainly suitable for the limestone powder, Fluorite powder, manganese mineral powder, chrome ore powder, etc.Material of roller is 9Cr2Mo.

3.Powerful hydraulic pressure briquette machine, which not only match the hydraulic pressure, but also the foce feeding equipments, which mainly suitable for some special dry powder materail, such as Magnesium Oxide, Aluminum dust, fluorite powders and various kinds of dry fine powders.

When we produce the machine, we will let you know which pressure is best for your raw material. And also can match the different pressure according to your special requirements. Welcome you to visit our facotry anytime and test the machine. Followed are thevideo linkfor this kind of machine for your reference:

http://www.youtube.com/watch?v=_neCKPXbcmE

http://www.youtube.com/watch?v=l1yUAGOjfAY

Two conditions for your raw material:

1. raw materail diameter: less than 3mm

2. raw material moisture content: about 15%

Parts of Main parameter:

| Model | Capacity(T/h) | Power(kw) | Pre-press power(kw) | Pump motor power(kw) | Roller material |

| 400 | 2-3 | 45 | 15 | 1.8 | chromium-molybdenum steel |

| 520 | 3-5 | 55 | 15 | 1.8 | chromium-molybdenum steel |

| 650 | 5-6 | 75 | 22 | 1.8 | chromium-molybdenum steel |

| 700 | 6-7 | 75 | 18.5 | 1.8 | chromium-molybdenum steel |

| 740 | 7-8 | 90 | 18.5 | 1.8 | chromium-molybdenum steel |

| 750 | 8-9 | 110 | 18.5 | 1.8 | chromium-molybdenum steel |

Text:

Different raw material need different pressure to squeezing them, so we recommend you to text the machine by the coal or your can send the raw material to our specialized lab to text them, thus you can choose most suitable machine.

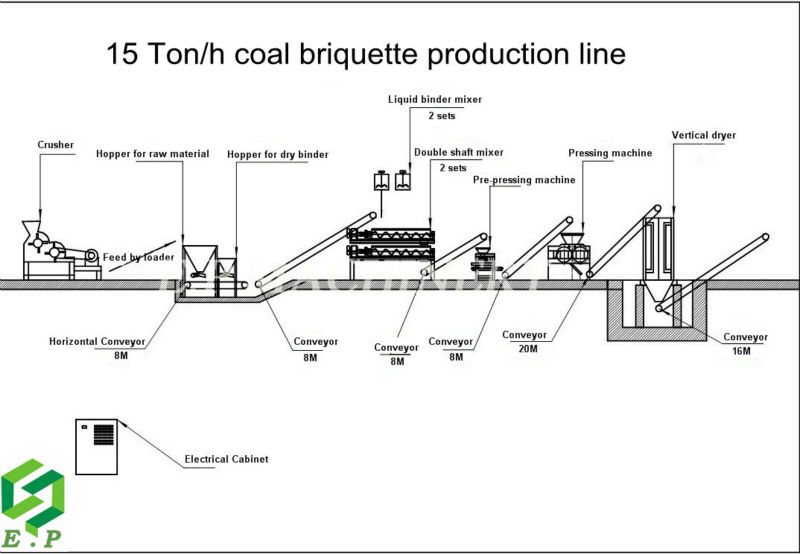

flow chart:

The different moulds for the balls:

Final products:

Bill of lading of parts of our different countries' customers for your reference:

Note:

Any more questions, please contact with us freely and i will be still online.

Thank you for your time!

| Packaging Detail:standard package: plywood case. |

| Delivery Detail:within 15 working days after we get the first payment |