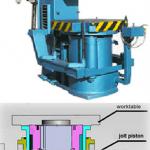

19 years history brand ZHEN GAO high pressure automatic hot chamber die casting machine

| Condition:New | Place of Origin:China (Mainland) | Brand Name:ZHEN GAO | Model Number:CM-268H |

| Dimension(L*W*H):4915*1690*2145 mm | Weight:10 ton | Certification:CE | locking force:268 ton |

| space between tie:560*560 mm | mold thickness:200-640 mm | casting weight:3.0/4.0 kg | vavle brand:Rexroth ,Yuken |

1 Company brief :

Guangzhou Zhen Gao Die-Casting Machinery Co., Ltd. was established in 1993,and located in Guanghzou city ,China .Major in manufacturinghigh pressure automatic hot chamber die casting machine(30ton—280ton)andhigh pressure automatic cold chamber die casting machine(130ton---650ton) . Good quality and favorable price .

2 Company advantage:

1.19 years of hot chamber die casting machine experience ,Professional

2.Computer Automatic control

3.CE,high quality

4.Competitive price

5. no chimney,clean,30% energy save

3 Machine advantage:

high pressure automatic hot chamber die casting machine

Model:CM-268H

1 computer controled system ,can store more than hundreds mould number ,and have fuction of memeory .

2 Two-stage injection adjustment can meet the high quality castings .

3 Very fast mould locking function,the production cycle is reduced effecrively .

4 The proportional flow rate control is adopted for slow speed injection,and fast slow can be adjusted by NC. It helps

runner system achieved best results in gas discharging ,and greatly raised products rate for die castings .

5 Good injection performance ,large ejection force ,and high die casting force ,good die casts solidification .

6 Unique energy saving design for proportional type of hydraulic system ,and it makes any adjustment freely achieved

theirbest status ,such as speed pressure in movement of mould opening /locking ,ejector and nozzle clamping unit .

7 Adopt computer control for automatic mould adjustment ,and is easy in operation .Precision for positon control

reached 0.1mm

8 Adopt safety device by electro-mechanic interlocking ,and ensure injection at safety door is closed and after mould

is tightlylocked and nozzle clamping unit ia closed .To make sure the safety .

9 Patent:furnace can save above 30% energy .

4 Specification of 268T high pressure automatic hot chamber die casting machine:

| DESCRIPTION | UNIT | CM-268H |

| DIE LOCKING SYSTEM | ||

| LOCKING FORCE | ton | 268 |

| TIE-BAR DIAMETER | mm | 100 |

| SPACE BETWEEN TIE(WXH) | mm | 560*560 |

| DIE HEIGHT(MIN/MAX) | mm | 200/640 |

| DIE STROKE | mm | 505 |

| SHOT POSITION (CENTRE/OFFSET) | mm | 0/100 |

| INJECTION SYSTEM | ||

| DIAMETER OF PLUNGER | mm | 70/75 |

| PLUNGER STORKE | mm | 180 |

| INJECTION FORCE(MAX) | ton | 16 |

| MAX SHOT WEIGHT(ZN) | kg | 3.0/4.0 |

| TRAVERSE STORKE | mm | 190 |

| CRUCIBLE CAPACITY | kg | 500 |

| ELECTRIC MELTING CAPACITY | kg | 450 |

| EJECTION SYSTEM | ||

| EJECTION FORCE | ton | 12 |

| EJECTION STORKE(MAX) | mm | 125 |

| Hydraulic power system | ||

| MOTOR POWER | KW | 22 |

| ELECTRIC FURNACE POWER | KW | 36 |

| OPERATION PRESSURE | kg/cm² | 145 |

| CAPACITY OF OIL TANK | L | 400 |

| ACCUMUL ATION | L | 36 |

| OTHER | ||

| MACHINE SIZE | mm | L:4915 |

| W:1690 | ||

| H:2145 | ||

| MACHINE WEIGHT | ton | 10 |

| Packaging Detail:based on customer request |

| Delivery Detail:witin 1 month |