1000ton Steel Silo For Sale Passed ISO9001&BV&CE Certification

| Condition:New | Capacity:16013m3,10993t | Material:Steel | Place of Origin:Shandong China (Mainland) |

| Brand Name:TSE | Model Number:TCK31119 | Dimension(L*W*H):31.168m*31.168m*23.74m | Weight:92.13tons |

| Diameter:31.168m | Layer:19 | Volume:14657stere | Silo bin height:16.79m |

| Total heighr:23.74m | Roof angle:25degree | Galvanized:275g/m2 | Usage:storage |

Specification:

Diameter: 31.168m

Layer :19

Capacity: 10993t

Volume: 14657m3

Coating: Galvanized 275g/m2

Total Height:23.74m

1000ton Steel Silo For Sale

Company introduction

Taian Shelley Engineering Co., Ltdis a professinal manufacturer in producing grain storage silo.

Our silos are made of hot sip galvanized steel sheets with 275g/m2 galvanized coating. All silos are of high efficiency and good quality.

The life span could reach 20 to 50 years.TSE have passed BV and ISO certification

Structural Outline:

1. The Silo Body

Includes the wall plate, column, manhole, roof ladders and so on.

(1) The wall plate

Our steel is hot galvanized, which makes it durable and weather resistant.

Our advanced bolts with spherical washer and the resisting-worn rubber are used to ensure the tightness and using period.

(2) Column

The column, made by the Z-bar, is used to reinforce the silo body. It is connected by junction panels.

(3) Manhole and Roof Ladders

There are inspection door and ladders inside and outside the silo body. It is convenient and accessible for any maintenance work.

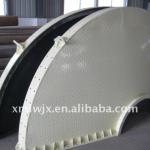

2. Roof

Roof is made up of radiated beam, roof cover board, tension ring, ventilator scoop, roof cap, etc.

All products made by TSE:

Silo Type(3)

A, Hopper bottom silo advantage is can natural flow, but it is capacity limited,capacity no more than 1500tons.

B, Flat bottom silo, which can support more sand, capacity up to 10000tons, and cheaper than hopper bottom silo, it need a sweep auger to run the grain out.

C, Cement hopper bottom silo combine A and B's advantage, capacity up to 5000tons, and it can natural flow without power.

Silo and Transmission Device Specification

Silo type | Hopper bottom silo | Flat bottom silo | ||

Bottom Cone Degree | 45 degree | 60 degree | ||

Diameter | 1.8m-11m | 1.8m-7.334m |

| |

Capacity | 5.4t-1428t | 5.8t-755t | 30t-10682t | |

Volume | 7.2m3-1855m3 | 8.4m3-701m3 | 39m3-13873m3 | |

Accessory Equipments: | ||||

- Bucket Elevator with capacity from 1 tone/hour to 400 tone/hour | ||||

Machines: | ||||

- Drying Machines ( Tower Type and Horizontal Type ) with capacity from 5 tone/hour to 50 tone/hour | ||||

Deatails :

Silo Body:Made of high quality galvanized steel corrugated sheet, connected by standard components.

Drag Conveyor: Horizontal transporting for grain

This is conveyor on silo roof as the picture shows.

Bucket Elevator: Vertical transporting for grain

Dedust system

Dedust Fan Collecting the air.

ORDER:

Polluted air from intake pit and precleaner→dedust net→cyclone→pulse dedust→dedust Fan→cleaned air.

Temperature monitoring system

The extension, 1 set per silo, the extension give the signal by wireless, the black part can produce power by solar,

the technical is mature and experienced.the monitoring cable has three cores, the sensor is impoeted from US.

Verntilation system

When the ventilation fan blow air into silo, the air goesin to ventilation net pipe, through the grain, then the temperature of grain is decreased.

Dryer and specification

We can supplly batch type dryer, it means we need several grs to decrease the moisture, different from circulating dryer,

it can keep grain's quality while circulating dryer's high temperature will damage the grain.

Engineering projects done before

In Honduros

Client from Australian in 2013.3

The final target is building suitable device for your production,

After get your enquiry and confirming all the details, we will give our design and offer for your inspection.

Edited by Fred

| Packaging Detail:no packing, packing my container |

| Delivery Detail:Within 2 months |