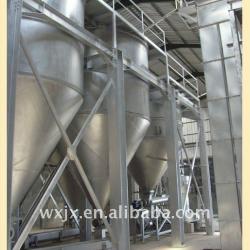

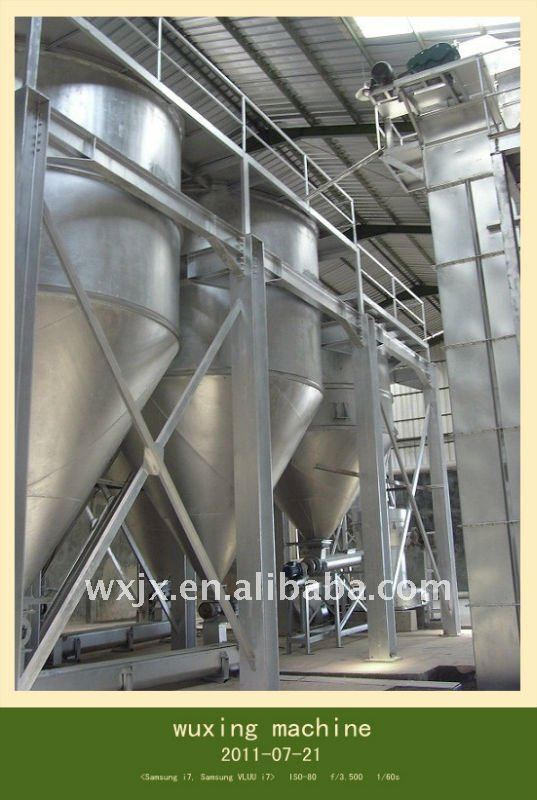

100000 T---gypsum powder production line

| Condition:New | Application:producing gypsum powder | Automatic Grade:Automatic | Production Capacity:100% |

| Place of Origin:Hebei China (Mainland) | Brand Name:wuxing | Model Number:wx-87 | Voltage:380V 220V |

| Power(W):120kw | Dimension(L*W*H):100x30 | Weight:100T | Features:stable |

| Certification:ISO CE | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | name::gypsum powder production line |

| one::hoist | two::Grain storehouse | three::Electromagnetic vibrating feeder | four::Raymond milling machine |

| five::Distribution cabinets | six::Vertical fry pan | seven::burner | eight::Induced draft fan |

| nine::Refractory bricks |

gypsum powder production line

specification:

ouput : 20000T-200000T

type: natural gypsum and Phosphorous gesso

Gypsum Powder Equipment Production Craft Introduction

1. Crushed process :

Crusher breaks up large sized gypsum ore to small granule less 25mm. And then, separator mill the granule to powder with required fitness and deliver to boiling furnace to calcine. The calcined gypsum powder is delivered to grog bin for saving or to production workshop for producing.

2. Boiling furnace process flow introduction

1) Principle :

The main part of boiling furnace is composed of thin and dense radiator pipes, which is filled with conduction oil to release the heat to the inside of the furnace. Equipped at the bottom of the furnace, the Roots blower makes the powder inside the furnace into the boiled state. The powder material, baked and dehydrated with crystallization water at certain temperature, flows out through the outlet automatically. The gypsum powder produced by this procedure has stable quality and well controlled crystallization water rate, initial and final set time. Further more, by using dry electrostatic cleaner, the equipment has over 95% dust collection efficiency and eliminate the dust pollution.

2)Simple and sustainable structure

Owing to the fluidization of material, furnace doesn’t have rotatable component so that it‘s easy to be built and almost free of maintenance. Thanks to the low temperature heat source, the furnace won’t be damaged by over heating and has longer operating life.

design :

production capacity: 20000T to 200000T

Output in one hour:5t finished product

The properties of product: meet GB9776-2008 requirements

technical date

quality standard

work system:

Broken parts: 300 days times 16 hours

Grinding parts: 300 days x 24 hours

Burning parts: 300 days x 24 hours

Store conveying parts: 300 days x 24 hours

the time: 3-5 T/h (product).

raw materials: natural gypsum (massive, the diameter is not more than 300 mm).

electricity requirement:

Three-phase AC380V, 50 hz;

Single-phase AC220V, 50 hz.

emissions standards:

No waste water discharge waste residue, emissions accord with state environmental protection emissions standards.

The construction plaster meets the People's Republic of building gesso national standards (GB9776-2008), meet the following requirements:

No | Item | Unit | Index |

| 1 | initial setting time | mim | ≥6 |

| 2 | Finial setting time | mim | ≤13 |

| 3 | 2hrupture strength | MPa | ≥2.2 |

| 4 | The content of the CaSO4·2H2O | % | ≤5% |

| 5 | The content of the CaSO4·1/2H2O | % | ≥75% |

| 6 | The content of the CaSO4Ⅲ | % | ≤5% |

structure simple, is not easy to damage:

equipment compact, covers an area of less

energy consumption is low, easy to reduce the production cost

honor:

| Packaging Detail:CONTAINER |

| Delivery Detail:60 DAYS |