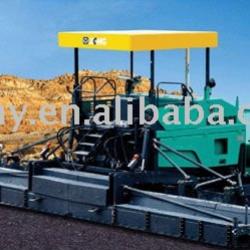

XCMG RP951A asphalt concrete paver

| Condition:New | Max. Paving Thickness:350mm | Paving Width:9.5m | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:XCMG | Model Number:RP951A | XCMG RP951A asphalt concrete paver:road machinery |

RP951A multi-function paver is a construction machine widely used for the paving project on the road base and surface for highway of various kinds of material. This type of machine has the most advanced technology, such as computerized system,ultra sonic sensor,electric auto-leveling system,faults self-diagnosis, dual-tamper and vibration, whick makes the complete machine work stably at speed, uniformly material flow, high pre-compaction, good smoothness, easy and convenient operation, all the key parts are purchased from international manufacturer to ensure the complete machine with the ssame quality and reliability as that of imported machine.Therefore, RP951A becomes the ideal equipment for paving job on stabilized soil for road base and asphalt concrete for road surface.

Main Feature

- Driving system with dual control for the right and the left tracks separately and the automatic-computer-control technology ensure the paving speed constantly.

- Adpoted with an advanced,mature,reliable and powerful DEUTZ BF6M1013E diesel engine.

- The fixed 3-in-1 hyper-power thermal exchanger discharges the heat compulsively and concentratively, so the paver can operate continuously under the condition of 50 centidegree for a long time.

- Four sets of separate full hydraulic transmission are adopted in the conveyor-auger system both on the right and left sides, and the ultra sonic sensor technology controls material lever.

- Material augers can move up and down expediently,so as to adapt different paving thickness and reduce material segregation

- The electric auto-leveling technology ensures the qualified smoothness.

- The technologies of dual tamper bars, eccentric vibrators and electric-heating system are adopted in the screed to gain the high pre-compacted density.

- Conveyor bottom plates, distributing augers, and screed bottom plates are made of high wearing-resistant alloy and imported wearing-resistant material to prolong the service life.

- Control panel shows directly and clearly all working parameter,and could be mounted either on right or left side.

- The mobile auto-leveling reference beam and contactless ultra sonic sensors could be available as an option.

| Item | Unit | RP951A |

| Basic Paving Width | m | 3 |

| Max Paving Width | m | 9.5 |

| Max Paving Thickness | mm | 350 |

| Paving Speed | m/min | 0~18 |

| Travel Speed | km/h | 0~2.4 |

| Theoretical Productivity | t/h | 700 |

| Capacity | t | 14 |

| Hopper Capacity | % | 20 |

| Gradeability | mm/3m | ≤2 |

| Pavement Evenness | % | ±0.02 |

| Transverse Leveling Accuracy | % | -1~3 |

| Centre Crown Ratio | BF6M1013E | |

| Engine Model | kw | 137 |

| Engine Power | r/min | 2300 |

| Engine Speed | L | 270 |

| Diesel Tank Capacity | t | 21.3~28.6 |

| Machine Weight | Hz | 0~50 |

| Tamper Vibration Frequency | Electric Heating | |

| Screed Heating | Automatic Control by Ultrasonic Sensors | |

| Auger and Conveyor Control | Digital | |

| Automatic Leveling Control |

l

| Packaging Detail:in nude. |

| Delivery Detail:in 5 days. |