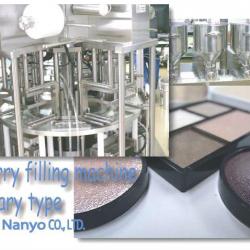

Wet powder filling equipment for make up

| Type:Filling Machine,Slurry filling machine | Condition:New | Application:Make up foudation eye shadow | Packaging Type:Aluminum and plastic pan |

| Packaging Material:Make up foundation eye shadow | Automatic Grade:Automatic | Driven Type:Electric(servo motor), pneumatic | Power:AC200V(3Phases) 30A-1line |

| Place of Origin:Japan | Brand Name:NANYO |

Slurry filling equipment(rotary type)

Slurry filling equipment rotary type is industrial machine for BIM and top filling. The size of this machine is smaller than line type. And this machine is designed as main product is BIM, so the speed of BIM is high. The mold cost is almost half of the line type.

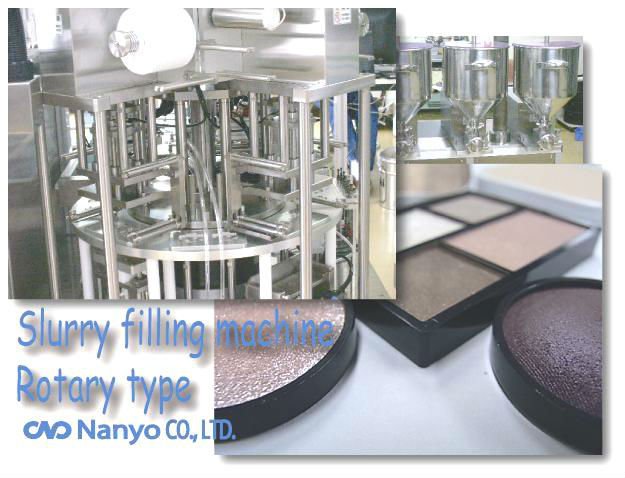

About slurry product(Wet powder)

The make up powder(foundation and eye shadow) need to be mixed with solvent (IPA, ethanol, isoparaffin, water and so on), to make it slurry(wet powder) state like mayonnaise. This slurry is filled in the pan from top or back with single or multi color in the same time. In the moment of press, the solvent is sucked from upper mold. After that, the product needs the drying process.

Feature of the slurry product

1 Less hardness difference

2 Easier to press the powder which has much pearl

3 The product become porous(such as sponge state), so the touch feeling is much better and smooth.

4 The small powder piece on the edge of pan is much less, so this small powder piece doesn’t fall down in the product shipment.

5 Good environment for operator regarding powder dust exposure, because powder dust doesn’t fly in the air.

Product feature and productivity of BIM(back filling)

The slurry is filled in the pan with the pressure from back side of the pan. So the pan must have filling hole on the bottom of the pan. The solvent is sucked from upper mold through the paper and cloth(screen). And final press is necessary according to the powder formula and design.

1 Good for small size of the pan and multi-cavity, and also multicolor, so normally used for eye shadow product.

2 Possible to fill sharp and narrow area with less hardness difference, which is impossible for dry powder.

3 Possible to produce doom shape, because the slurry is filled with pressure.

4 It is possible to reduce the cost for the pan, mold of the pan and assembly process, as compared with dry powder press product, because it is possible to fill several color in the same time in the pan.

5 Possible to reduce pan cleaning process, because powder doesn't put on the outside of the pan, except around filling hole.

6 The pan needs to have hole in the backside of the pan to fill slurry.

Product feature and productivity of top filling

The slurry is filled from the top side of the pan with every time same quantity. The first press and final press is necessary to suck the solvent through the paper and cloth.

1 It is possible to fill slurry in short time, so normally used for foundation which needs much powder quantity, and also used for face color with multicolor.

2 In the case of the multicolor with top filling, it is less cost than dry powder press.

3 It is unnecessary to make the hole on the back side of the pan, and possible to use both aluminum and plastic pan.

Feature of the slurry filling equipment(rotary type)

1 All setting parameter which has influence on the product quality is from touch panel, and it is possible to save and read out these setting parameters.

2 The servo motor is used for filling pump. This servo motor is controlled by 2 system, one is the torque control (pressure filling) for back filling(BIM), and the other is position control(same amount filling) for top filling. It is possible to set the filling amount, filling pressure, filling speed for each pump or each color.

3 The servo motor is used for upper mold up/down movement in press unit. For the press, the upper mold goes down with high speed with position control to reduce free running time, and the servo motor control is switched to torque control for press, so it is possible to reduce the time for press.

4 The actual pressure to the powder in the moment of the press is indicated in the screen every time, so it is possible to monitor, if the machine is running appropriately or not, too.

5 In case of top filling, the special figure of the upper mold is used in the first press, to avoid leaking the slurry goes outside the pan.

6 If the increased safety is required for the explosion-proof, inside of the electric box is pressurized by the air to avoid the flammable gas go inside of the electric box.

Specification

| Power source | Electric : AC200V(3Phases) 30A-1line Air : More than 0.5Mpa-1 line |

| Object | Make up powder for foundation, eye shadow, face color and so on |

| Number of color | 4 - 6 colors(Pumps) |

| Pan size | 2 pans in 1 holder : 60mm x 70mm(max) 4 pans in 1 holder : 30mm x 60mm(max) 8 pans in 1 holder : 25mm x 30mm(max) |

| Speed | 2 pans in 1 holder BIM : 16pcs/min 4 pans in 1 holder BIM : 32pcs/min 8 pans in 1 holder BIM : 64pcs/min 1 pans in 1 holder Top filling : 8pcs/min *In case of the filling and press time is less than 4 sec |

| Operator | 2 - 4(Pan supply, product ejection) |

| Transportation | Turn table |

| Press mechanism | Servo motor, Pressure : 50kgf - 350kgf |

| Pump mechanism | Servo motor, BIM : Torque(pressure) control, Top filling : Position control |

BIM(back filling) product, 3-D shape is possible

BIM filling unit

1st and 2nd press unit

Pump unit

| Packaging Detail:wooden packing |

| Delivery Detail:Normally 4 month after order and first down payment receiving |