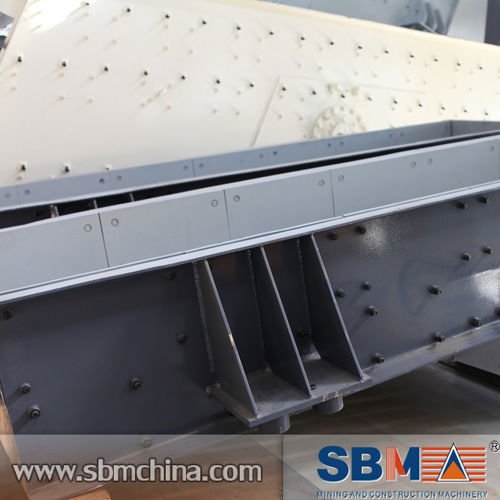

Vibrating Feeder Machine

Vibrating Feeder Machine,Vibrating Feeder,Feeder, 1 Easy maintenance., 2 Easy to adjust., 3 No pollution., 4 Reliable operation. - details see: https://www.machineto.com/vibrating-feeder-machine-10316081

| Condition:New | Place of Origin:Shanghai China (Mainland) | Brand Name:SBM | Model Number:Various |

| Year Production:2010 | State Production:New | Type:Feeder Machine |

Vibrating Feeder Machine,Vibrating Feeder,Feeder

Vibrating Feeder

VibratingFeeder is a kind of linear direction feeding equipment. It featuressmooth vibrating, reliable operation, long service life and beingsuitable for feeding. They are widely used in mining,building-material, silicate and chemical industry in the crushing andscreening plants.In the Sand-Stone production line, it can send materials to crusherevenly and continuously and at the same time, it can screen materialsroughly. It can be used in these areas such as metallurgical industry,coal mining industry, mining-selecting, building, chemical and grindingindustry, etc.

Why to choose

This SBM vibrating feeder is manufactured on the theory of vibration, whichis widely used in mining, construction materials, silicate and chemical industry.The vibrating feeder can provide ores and rocks within 500mmfor the next working procedure. it can supply the materials equablywith no-stop.

Working Principle

Vibrating feeder consists of vibrating frame, spring, vibrator, motorvibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the twoeccentric shafts start rotating to produce a linear huge power whichforces the feeder to vibrate. Through the vibration, The materials willslip and sling on the funnel, moving forward, when the materials passthe screening part, smaller parts will fall down, avoiding the furthercrushing, so screening purpose can be reached.

Vibrating feeder consists of vibrating frame, spring, vibrator, motorvibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the twoeccentric shafts start rotating to produce a linear huge power whichforces the feeder to vibrate. Through the vibration, The materials willslip and sling on the funnel, moving forward, when the materials passthe screening part, smaller parts will fall down, avoiding the furthercrushing, so screening purpose can be reached.

Benefits & Features

1. Stable and long span life.

2. Easy to adjust.

3. Reliable operation.

4. Easy maintenance.

5. No pollution.

Note: This specification is just reference, any changes are subject to the products.

1. Stable and long span life.

2. Easy to adjust.

3. Reliable operation.

4. Easy maintenance.

5. No pollution.

Vibrating Feeder Specification

| Model | Max input size(mm) | capacity (t/h) | motor power (kw) | Installaition Slope | weight (kg) | Size of Funnel (mm) |

| GZD-180×80 | 300 | 30-80 | 2×1.5 | 0-10 | 0.8 | 1800×800 |

| GZD-300×90 | 500 | 40-100 | 2×2.2 | 0-10 | 1.5 | 3000×900 |

| ZSW-380×96 | 500 | 90-100 | 11 | 0° | 3.98 | 3800×960 |

| ZSW-490×96 | 500 | 120-240 | 15 | 0° | 5.5 | 4900×960 |

| ZSW-490×110 | 580 | 120-280 | 15 | 0° | 5.72 | 4900×1100 |

| ZSW-590×110 | 600 | 280-500 | 22 | 0° | 6.13 | 5900×1100 |

| Packaging Detail:exporting standard |

| Delivery Detail:30 days |