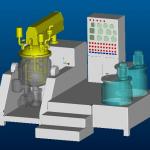

V-shape Powder Mixer/Blender

| Mixer Type:Agitator | Application:Powder | Additional Capabilities:Disperse | Place of Origin:Shanghai China (Mainland) |

| Brand Name:SIEHE | Model Number:SZX Series | Capacity:80-1200 Kg |

V-shape Powder Mixer/Blender

1. Intro

V-shape Powder Mixer is a brand-new mixer. It is characterized in high efficiency, low energy consumption, and little residue. The machine is widely used for mixing powder-powder, powder-granule, especially for mixing powder or granule materials with good fluidity in pharmacy, food and chemical industries.

2. Main Features

a. Compact Structure, easy operation, clean to clean, stable operation without noise.

b. Suitable for mixing various materials, uniformity can comes up to 98%.

c. Vacuum materials feeding and butterfly valve discharging are optional to realize dust-free operation.

d. Electric system is with motor over-load protection.

e. Adjustable speed. Timing device and strong agitator can ensure the mixing uniformity effectively.

3. Reference Parameter

Power Supply: 380V, 50/60Hz (Can be customized)

Materials: The part contacting with materials can be SS304 or SS316L.

Pipeline Connection: Flange, Quick-connection or Screw

| Model | Motor(kw) | Speed(rpm) | Quantity (kg) | Shape Size (mm) | Weight (kg) |

| SZX-0.1 | 1.5 | 2/108 | 30-60 | φ750*1580 | 250 |

| SZX-0.5 | 3 | 2/108 | 150-300 | Φ1150*2320 | 650 |

| SZX-1 | 5.5 | 2/57 | 300-600 | Φ1480*2850 | 1200 |

| SZX-2 | 5.5 | 2/57 | 600-1200 | Φ1820*3510 | 1500 |

| SZX-3 | 7.5 | 1.8/57 | 900-1800 | Φ2050*3800 | 2300 |

| SZX-4 | 11 | 1.8/57 | 1200-2400 | Φ2250*4480 | 2500 |

| SZX-5 | 15 | 1.8/57 | 1500-3000 | Φ2350*4720 | 2800 |

| SZX-6 | 15 | 1.8/57 | 1800-3600 | Φ2560*4980 | 3000 |

| SZX-8 | 18.5 | 1.8/57 | 2400-4800 | Φ2780*5360 | 4500 |

| SZX-10 | 18.5 | 1.8/57 | 3000-6000 | Φ3020*5810 | 5500 |

| SZX-15 | 22 | 1.8/57 | 4500-9000 | Φ3460*6510 | 6800 |

| SZX-20 | 37 | 1.8/57 | 6000-12000 | Φ3810*7420 | 7800 |

| SZX-25 | 45 | 1.8/57 | 7500-15000 | Φ4090*7800 | 9800 |

| SZX-30 | 55 | 1.8/57 | 9000-18000 | Φ4350*8200 | 11800 |

Remarks:

*The above listed Max. processing capacity is calculated as per powder with specific gravity 1 as medium. The model selection should depend on the comprehensive factors such as materials viscosity, specific gravity etc.

*If works under special environment such as high temperature, high pressure, explosive, combustible, corrosive etc, correct data is required for correct model selection.

*The above data and picture is subject to change without notice. The accurate parameter should be subject to the object.

*Not all products are listed. For more, please contact with our sales engineer.

| Packaging Detail:Wooden package with steel frame. |

| Delivery Detail:45-60 days after receiving the deposit. |