Titanium plate heat exchanger supplier

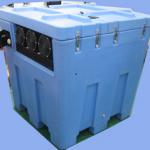

| Type:heater and cooler | Place of Origin:Liaoning China (Mainland) | Brand Name:SUCCESS | Model Number:S6B-14 |

| Certification:ISO 9001:2008 | Frame plate:Epoxy painted | Nozzles:Carbon steel | Lined:Titanium |

| Plates:Titanium | Gasket:Viton | Connection Size:60mm | Maximum heat transfer surface:38M2 |

| Height:920mm | Width:320mm | Pressure:1.0 to 2.5MPa |

Gasketed Plate Heat Exchanger

Each plate is provided with a gasket, which seals the flow gaps to atmosphere and the media from one another. The plate package is mounted in a rack consisting of a fixed number of plates. Two pressure plates clamp this package together with tie rods. Single pass and multi-pass arrangements are standard with a surface area of up 1500m2 in one unit. Pure counter flow is employed to achieve maximum possible heat transfer.

Materials

| Plate material | Applicable fluid |

| Stainless steel(AlSl304,AlSl316L) | Purified water, river water, edible oil, mineral oil |

| Titanium and Ti-Pd | Sea water, salt water, salt chemicals |

| 20Cr, Rs-2, SMO254 | Dilute sulphuric acid, dilute aqueous, solution of salt chemicals, lnorganic solution |

| Nickel | High temperature and high concentration of caustic soda |

| HASTELLOY (C276,D205,b2G) Alloy | Concentrated sulfuric acid,hydrochloric acid and phosphoric acid |

| Black lead | Hydrochloric acid,medium-concentration sulfuric acid,phosphoric acid and fluoric acid |

Model and parameters of plate heat exchanger

SUCCESS PHE Technical data

S6B-14

Parameters | S6B-14 | |||

Heat transfer area of plate2 | 0.14 | |||

Chevron depth mm | 2 | |||

Chevron angle º | 1 | 58 | ||

2 | 118 | |||

Chevron normal pitch mm | 6.25 | |||

Equivalent diameter mm | 4 | |||

Hole diameter mm | 59 | |||

Center distance of holes mm | H | 640 | ||

W | 140 | |||

Center distance suspension mm | 714.4 | |||

Cross section of single passage mm² | 432 | |||

Overall dimension of plate mm | L | 747 | ||

W | 248 | |||

The max. heat transfer coefficient (water to water)W/ m².ºC | 7500 | |||

The max. Working temp.ºC | 180 | |||

The max. Testing pressure Mpa | 2.5 | |||

The max. Flow rate M³/h | 50 | |||

No. | ASSY Area m² | No.of plate | The max. Flow rate M³/h | Dimension mm | Theoretical weight Kg | ||

| L | W | H | |||||

| 1 | 5 | 36 | 50 | 400 | 340 | 900 | 180 |

| 2 | 10 | 72 | 50 | 600 | 340 | 900 | 200 |

| 3 | 15 | 107 | 50 | 800 | 340 | 900 | 230 |

| 4 | 20 | 143 | 50 | 1000 | 340 | 900 | 260 |

| 5 | 25 | 179 | 50 | 1100 | 340 | 900 | 280 |

| 6 | 30 | 215 | 50 | 1200 | 340 | 900 | 310 |

Flange connection

Application

Marine - Seawater isolation exchanger, central cooling, jacket fresh water cooling, lube oil cooling.

Power - Lubrication oil cooling, diesel engine cooling, heat recovery, auxiliary cooling circuit isolation, geothermal applications.

Refinery - Brine cooling, crude oil/water

Oil & Gas - Sea water coolers, crude oil heat treatment

Interchanger, treated crude oil/untreated crude oil interchanger

| Packaging Detail:wooden case or according to customer requirement. |

| Delivery Detail:7 to 15 working days |