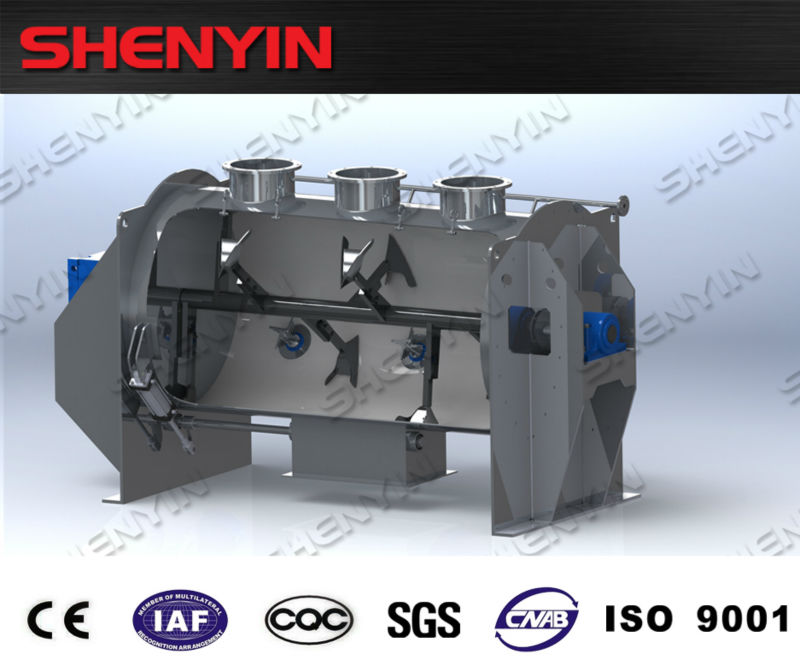

SYLD CHEMICAL MIXER

| Condition:New | Mixer Type:coulter | Product Type:Chemical/Meta/Plastic/Dry Mortar/Feed/Food/Cermaic | Application:Powder/Liquid/Fluid |

| Additional Capabilities:Heating, Cooling | Place of Origin:Shanghai China (Mainland) | Brand Name:SHENYIN | Model Number:SYLD |

| Max. Loading Capacity:500L-12000L | Voltage:As customer required | Power(W):As customer required | Dimension(L*W*H):See chart |

| Certification:CE/SGS/IAF/SNAB/ISO9001-94/ISO9001-2000/ISO9001-2008 | Warranty:12 months | CHEMICAL MIXER:CHEMICAL MIXER |

Working Principle:

In the first case the mixing shaft and the tools are

horizontally installed, thus achieving, at corresponding

movement, a product reaching from a loose product

bed up to a mechanically generated fluidised bed.

In the second case the mixing shaft is installed in vertical direction, whereby a socalled vortex is built at corresponding movement. The installation of fast-rotating chopper heads enables the mixing of products tending to lump formation. Due to the mixing tools, the material to be mixed is hereby specifically fed to the activity area of the chopper head. Besides the conventional ploughshare mixing tools a large variety

of modified mixing tools is available, facilitating an

optimumadaptation of the mixing tools to the individual material.

Standard Features:

·Stainless Steel or Carbon Steel

·Plough agitator for center discharge

·Designed for normal temperature and normal atmospheric pressure

·Feed Nozzle

·Dust Nozzle

·Manually operated or Pneumatic operated flap valve

·Packing Seal

·Safety limit switch on inspection door

Optional Features:

·Carbon Steel, Stainless Steel 304, Stainless Steel 316L·Different type of plough according to material characteristics

·Internal pressure

·Sanitary type construction·Horsepower to suit higher density materials

·Explosion-proof motors·Controls such as variable frequency drives, motor starters and operator stations are available

·Spray nozzles for liquid introductionJacket for heating or cooling

into the open side of the square cylinder can be used as observation and cleaning up the door for use, standard gasket, lock fastening; limit switch can be installed.

the feeding method can also be made of this type of continuous mixer, mixer, valve by adjusting the size of the opening material in the cylinder body to control the residence time in order to control the purpose of mixing homogeneity.

| Packaging Detail:Packaging Detail: Wooden Case |

| Delivery Detail:30 days |