super quality oilfield use drill pipe from China with competitive price

| Place of Origin:Jiangsu China (Mainland) | Brand Name:SHUNCHANG | Type:Drill Pipe | Machine Type:Drilling Equipment |

| Certification:API | Material:Carbon Steel,steel | Processing Type:Forging | Use:Well Drilling |

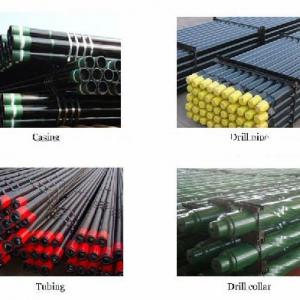

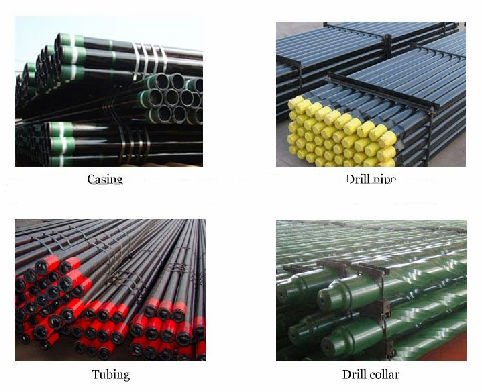

Nantong Yongda Pipe Industry Incorporated Company is located in Hai’an Industrial Zone, at the Yangtze River Delta, Jiangsu Province, China. The Company manufactures drill pipes, heavy weight drill pipes, drill collars, kellys, casings, tubings and other products. Nantong Yongda Pipe Industry Incorporated Company’s 111,000 square meter factory and office buildings are located on our 320,000 square meter property. We employ a staff of 418 people, including 165 technicians, and 81 engineers.

The machine park installed in our facility includes only state-of-the art, modern machinery and equipment, designed to guarantee the manufacturing of highest quality drilling and production tubulars. Most of the critical equipment, including friction welding machines, inspection equipments, upsetters, etc. are improved versions of commercially available equipment on the international market (USA, Europe, Japan), specifically adapted to enable to enable us to meet the highest industry standards. We have a production capacity of 100,000 tons of heat-treated drilling and production tubulars.

Among many of our proprietary technical in-house innovations and developments, we utilize a set of unique upset machines for drill pipe body, which produce upset sections (ID AND OD) longer than 195mm.This technology increases the strength and toughness of the drill pipe, and also extend the life of drill pipe so that the drilling costs are reduced.

All our raw materials: pipe, tool joint material, coupling material, etc. are bought from only the very best sources. Before they enter our manufacturing processes, they must be inspected and approved by our well-equipped in-house laboratory, to verify traceability, physical, chemical and dimensional compliance.

As we are an integrated oil field tubulars manufacturer, we have ultimate control of ALL manufacturing steps. Our production and inspection procedures are meticulously adhered-to, by our highly trained production and inspection staff and quality control engineers. Thus, we can guarantee consistent and uniform product quality for ALL our products.

We have the QHSE certificates, and API SPEC 5DP, API 5CT certificates. We also have Welding Certificates from American ARNCO Company.

The raw material for these drill pipes are all the alloy steel produced by BAOSTEEL, and their both ends will be up-setted without weilding. After examination, the pipes will receive heat treatment and threading treatment. Finally, the pipes are plated with nickel-phosphor to improve the hardness and tightness of the threads. A series of test including hardness test, matellurgical structure,physical property will be carried out before packed.

See the drill pipe catologue for referance:

HWDP:

Factoyy and equipement scene:

| Packaging Detail:as per customer's requirement |

| Delivery Detail:1 month |