stainless steel balance weave wire conveyor wire mesh

| Place of Origin:Shandong China (Mainland) | Brand Name:Haofa | Model Number:B-WH45 | application:convey&baking |

| character1:customer according | character2:durable | character3:solid |

balanced weave conveyor wire mesh is produced with alternating right and left hand spirals joined by crimped connector rods.

It is the most commonly used wire mesh belt due to its range of opening sizes.

Balanced Weave Belts are used for heavy duty applications or produced with light wire to convey small parts.

This design offers straight tracking and long belt life.

Typically produced with round wire, the use of flattened wire provides a flat carrying surface.

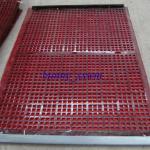

1:high quality flat wire mesh belt

2:material:stainless steel

3:features:smooth,flat surface,easily clean,durable

flat wire mesh belt,conveyor mesh belt

Features:

1)Open mesh construction for quick drainage and free air circulation.

2)A smooth, flat surface.

3)Sanitary -- easily cleaned.

4)Easy replacement of damaged or worn sections.

5)Endless splicing.

6)Economical versus alternative metal conveyor belts.

7)High strength to weight ratio.

8)Positive sprocket drive.

Typical Application:

1)Canning and food preparation.

2)Baking and freezing food.

3)Parts cleaning.

4)Parts painting and drying.

5)Product sorting, assembly and packaging.

The flat wire belting is a continuous assembly of flat wire pickets connected by straight round wire inserted through positioned holes. It has a smooth carrying surface which makes it popular in the canning and food processing industries, as well as the drying, freezing, washing, and parts transfer processes.

Advantages:

Smooth flat surface.

1)Open mesh construction for quick drainage and free air circulation.

2)A smooth, flat surface.

3)Sanitary -- easily cleaned. · Economical versus woven wire belts.

- flat wire mesh belt,conveyor mesh belt

| Packaging Detail:wooden box |

| Delivery Detail:10 days |