sprinkler cooling tower price

| Condition:New | Cooling Type:Counter Flow | Material:Metal | Place of Origin:Shandong China (Mainland) |

| Brand Name:Heng An | Model Number:BNK702 | Voltage:220V/380V/415V etc | Dimension(L*W*H):2500*2410*4050 |

| Weight:1T~10T | Certification:CTI,ISO,BV,CCS,etc | Warranty:12Months | After-sales Service Provided:Overseas service center available |

| Cooling coil material:stainless steel/Hot-Dip Al-Zn Alloy-Coated Steel Sheet etc | Water flowing rate:0.001% | Maintenance:with access door and ladder | Structural steel supplier:Bao Steel |

| Anti-corrosion way:The overall heat invasion zinc | Nozzle material:ABS | Design Center:National Heat Exchange Center(in Shandong University) | PLC:Omron,Siemens,ABB |

| color:As customer requirements | Circulation pump:15 KW * 2 PCS |

Closed cooling tower :

- Decreases the level of energy consumption

- Low environmental impact and conserves natural resources

- Less maintenance and heat rejection at the lowest possible energy input requirements via:

- Premium efficient/VFD duty fan motors are standard

- High efficiency, low horsepower axial fans

- Patented combined flow technology

- Closed loop cooling, which minimizes process fouling

- Minimizes the potential for scaling and fouling

- Reduces evaporation directly off the coil

A. Working Principles:

Working fluid(water,oil o other liquid) i flowing inside of the coils,which is enwrapped by spray water on the outside. The heat of water is transferred by coil and become the saturated vapor when meet the water and air. Teh heat is exhausted out of the tower by the tower by the top fan; water is collected back to the bottom tank and circulates continuously. Teh spray water is cooled down via PVC radiation fin in the process of circulation, and flows n the same direction with the fresh wind. The coil mainly takes sensible heat travel style. The most benefit of this style is can avoid scale formation on the outside of th coil. And this will apply especially to dealing with high temperature fluid (e.g. 60°C) or the fluid need big temperature difference (e.g. 60°Cto 35°C).

B.Detailed information:

| Part of BHX series Combined-flow Closed Cooling Tower Parameter | ||||||

| Type | Total Length | Single cabinet width | Height of the cooling coil | Coil straight length | Coil number | |

| unitary | BHX-245 | 1820 | 1740 | 620 | 1520 | 56 |

| BHX-280 | 1820 | 1740 | 620 | 1520 | 56 | |

| BHX-320 | 1820 | 1740 | 620 | 1520 | 56 | |

| single box | BHX-380 | 1820 | 1740 | 1090 | 1520 | 36 |

| BHX-430 | 1850 | 1740 | 1090 | 1520 | 36 | |

| BHX-475 | 1850 | 1740 | 1320 | 1520 | 36 | |

| BHX-495 | 1850 | 1740 | 1320 | 1520 | 36 | |

| BHX-550 | 1950 | 1840 | 1090 | 1620 | 56 | |

| BHX-595 | 1950 | 1840 | 1090 | 1620 | 56 | |

| BHX-670 | 1950 | 1840 | 1320 | 1620 | 56 | |

| BHX-700 | 1950 | 1840 | 1320 | 1620 | 56 | |

| BHX-735 | 1950 | 1840 | 1320 | 1620 | 56 | |

| double box | BHX-900 | 3590 | 1740 | 1090 | 3200 | 36 |

| BHX-960 | 3590 | 1740 | 1320 | 3200 | 36 | |

| BHX-1050 | 3590 | 1740 | 1320 | 3200 | 36 | |

| BHX-1165B | 3790 | 1840 | 1320 | 3400 | 40 | |

| BHX-1285B | 3790 | 1840 | 1320 | 3400 | 40 | |

| BHX-1335B | 3790 | 1840 | 1320 | 3400 | 40 | |

| BHX-1420 | 3790 | 1840 | 1320 | 3400 | 56 | |

The above is only a few models. We design cooling tower based on your situation

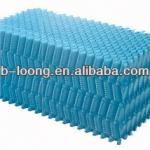

C.Products show:

Our products are mainly used for: Our products are mainly used for:

1, cooling the induction furnace of steel plant and jobbing foundries, cooling rolling machine, cooling the quenching tank, cooling the continuous casting.

2,cooling the hydraulic oil, electroplating solution, quenching oil, circulating water production line and other cooling industrial fluid;

3,cooling the water source heat pump system, computer room air conditioning system, auxiliary cooling system and other cooling air conditioning systems .

4,cooling the air compressor water jacket, injection mold, transformers, engine water jacket and other cooling industrial facilities.

5,cooling other equipments, such as power plants, paper mills, food factories.

If any questions ,Pls contact with me

| Packaging Detail:Wooden packing, Plywood board packing, 20 feet container, 40 feet container for the cooling tower. |

| Delivery Detail:in 30 days after the deposit of the cooling tower |