Single Complete Catfish Feed Pellet Making Machines

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:SHARE | Model Number:XGJ580 |

| Voltage:380v/440v | Power(W):160kw | Dimension(L*W*H):2900*1300*2400mm | Certification:CE ISO,CE/ISO |

| Warranty:1 Year | After-sales Service Provided:Engineers available to service machinery overseas | Name:Catfish Feed Pellet Making Machines | Other name:Complete Catfish Feed Pellet Making Machines |

| Type:Vertical Ring die | Output:1800kg/h | Power:160kw | Pellet Size:4-10mm |

| Features:High output, low conption |

Single Complete Catfish Feed Pellet Making Machines

1.Catfish Feed Pellet Making Machines description:

The XGJ and SKJ biomass pellet fuel machine are applied to the materials with low adhesiveness and low shaping, such as the rice husk, sunflower husk, peanut shell and other fruit shell; branch, trunk, bark and other wood waste; a variety of crop straws; rubber; cement, ash and other chemical materials. It is the ideal pressing shaping equipments with low investment and high profit.

2.Catfish Feed Pellet Making Machinesinner pictures:

3.Catfish Feed Pellet Making MachinesParameter:

| Model | Power (kw) | Pellet Size (mm) | Output (kg/h) | Dimension (mm) |

| XGJ550 | 75 | 4-10 | 1000 | 2630*1000*2400 |

| XGJ560 | 90 | 4-10 | 1500 | 2600*1300*2300 |

| XGJ580 | 160 | 4-10 | 1800 | 2900*1300*2400 |

| XGJ850 | 220 | 4-12 | 2500 | 3300*1400*3100 |

| XGJ880 | 315 | 4-12 | 3300 | 3800*1680*3400 |

| XGJ1050 | 365-450 | 4-30 | 4000 | |

| XGJ1250 | 550-660 | 4-30 | 6000 |

4.Catfish Feed Pellet Making MachinesAdvantages:

1.Vertical feeding.The inlet and the same as the diameter of the ring die, increasing the feed rate.

2.Stationary Ring die, Pressure roller rotation, by centrifugal force, the material evenly spilled into the annular abrasive face.Adhere to the processing surface of the ring die.

3.Double-layer dies, up and down dual-use, reduce the cost, enhance the efficiency, can be dual-use, high capacity, energy saving.

4. One die, different diameters, with different specifications to pelletize.

5. Tapered bores, the compression ratio increases, increasing the strength of the pellet.

6. Ring die, vertical structure, and good for cooling the pelletizing room.

7.Separate inverter unloading device, to ensure that the rate of Pellet formation.

5.Catfish Feed Pellet Making Machines RELATED MACHINES IN OUR FACTORY:

OUR COMPANY OTHER KINDS OF BIOMASS PELLET MAKING MACHINES FOLLOWING:

| Model | Output(kg) | Power(kw) | Pellet size(mm) | Weight(kg) | Dimension(mm) |

| SKJ2-120 | 20-40 | 3-4 | 4-6 | 50 | 1150*300*550 |

| SKJ2-150 | 30-50 | 7.5-4 | 4-8 | 150 | 1260*400*650 |

| SKJ2-200 | 50-100 | 11-4 | 4-6 | 200 | 1300*500*850 |

| SKJ2-250 | 100-300 | 15-4 | 4-6 | 500 | 1400*600*1000 |

| SKJ2-280 | 200-400 | 22-4 | 4-6 | 650 | 1760*670*1600 |

| SKJ2-300 | 300-500 | 30-4 | 4-8 | 760 | 1860*670*1600 |

| SKJ3-350 | 300-600 | 37-4 | 4-10 | 2200 | 1900*850*1750 |

| SKJ3-450 | 500-800 | 55 | 4-10 | 4300 | 2300*1100*1900 |

| SKJ3-550 | 1000-1500 | 90-6 | 4-12 | 5500 | 2350*1000*2050 |

| SKJ3-800 | 1500-2500 | 130-160 | 4-12 | 6800 | 3200*1235*2700 |

| SKJ4-1200 | 3000-5000 | 280-320 | 4-15 | 19000 | 3800*1700*4200 |

1. The SKJ biomass pellet fuel machine is mainly applied toSmall output of biomass material make the biomass fuel pellets.

2. The SKJ biomass pellet fuel machine diameter of input materials is 2-8mm, the smaller the better. The moisture of raw materials is about 13%-20%, the moisture of finished pellets is about 10%. The machines can be both with motor and diesel engine can satisfy the Different customer needs.

3. Under the advanced technology adopting automobile differential gear OrHorizontal gearbox, the capacity of the pellet machine is high, energy consumption is low and the operation is very convenient.

4.Because the reasons for Flat die, so it will be small output , so the machine is small, can be easily disassembled for maintenance of the pressure roller and flat die.

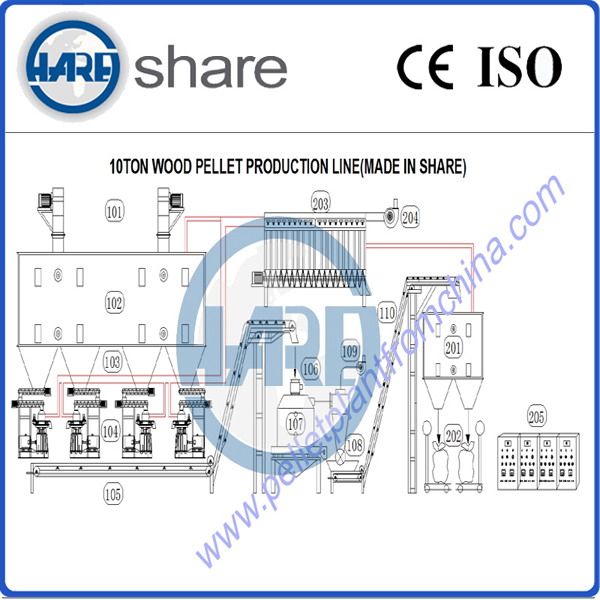

6.Catfish Feed Pellet Making Machines RELATED COMPLETE SETS

WE Installed completely all over the world.

101. [Wood chipper], 102. [Belt conveyors]. 103. [Hot stove]. 104. [Rotary Dryer].

105. [Blower]. 106. [Cyclone].107. [Air-lock].

201. [Belt conveyor]. 202. [Multifunction Hammer mill]. 203. [Blower].

204. [Cyclone]. 205. [Air-lock].

301. [Materials Inductor]. 302. [Surge bin].

303. [Screw conveyor]. 304. [Rotate conditioner]. 305. [ biomass pellet fuel machine ]. 306. [Belt conveyor].

401. [Elevator]. 402. [Air-lock]. 403. [Counter Flow Cooler]. 404. [Blower].

405. [Cyclone]. 406. [Air-lock]. 407. [Belt conveyor].

502. [Screening machine] . 503. [Materials Inductor]. 504. [Pellet silo]. 505. [Packing machine].

601. [Dust collecting pipe]. 602. [ Baghouse].

701. [EL control boxes].

7.Catfish Feed Pellet Making Machines PROFESSIONAL MANUFACTURER, WHY HAVE TO CHOOSE US:

1. We have been in this field for 22 years, GOOD QUALITY and HIGH CREDIBILITY makes us stand.

2. If the order more than USD30000.00, we will be free to debug the machines. You are only in charge of the air tickets and board and lodging.

3. If the complete plant needs our installation, you will only need to pay us USD 50 per day per person, and the air tickets and board and lodging.

Any question, feel free to connect us following:

Manager: Megan Sun

MOB: 0086 150 531 77578

Skype: megansunny

Catfish Feed Pellet Making Machines

| Packaging Detail:Catfish Feed Pellet Making Machines packing:1.normal packing. 2.wooden case packing. 3.iron box packing. Please choose what you need packaging form, we sincerely service for you .thanks . |

| Delivery Detail:7 day |