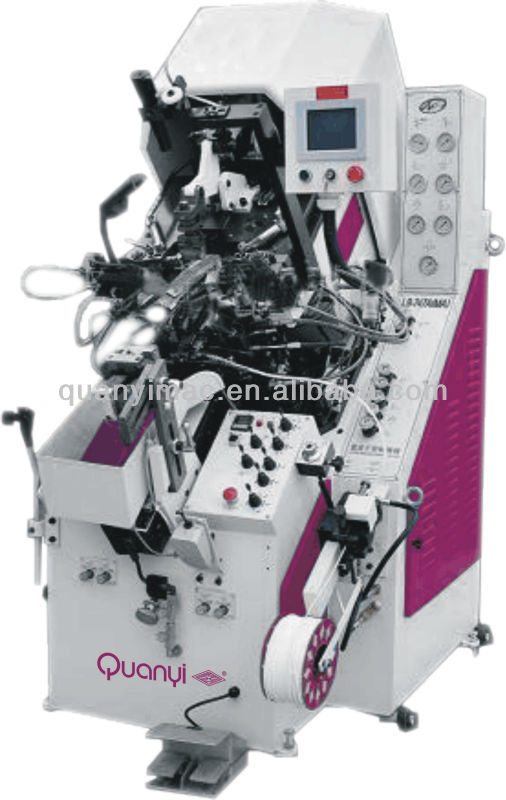

shoemaking machine Computerized shoe Lasting Machine

| Condition:New | Automatic Grade:Automatic | Production Capacity:2/day | Place of Origin:Guangdong China (Mainland) |

| Brand Name:QUANYI | Model Number:QY2B9 | Voltage:380V | Power(W):2.2kw |

| Dimension(L*W*H):1960*1050*2000mm | Weight:800kg | Warranty:1year | After-sales Service Provided:Engineers available to service machinery overseas |

| color:blue with white |

QY2B9 Auto-cementing Computerized Toe Lasting Machine

1. The machine is equipped with an automatic cementing system. For being lasted, the insole and upper do not need manually cemented in advance, which save much labor cost. Moreover, the shoe will be never de-cemented after being lasted, and the shape of the shoe has been perfected.

2. With the design of specially tracked wipers, the all-around multipoint press fitting ensure the upper to be evenly attached to the last after lasting. No gathering will be occurred and the quality of the product is excellent and perfect.

3. The mechanism of toe pad pressing is adjusted by a 2-step dual cylinder pressure system, which will create a perfect effect both during the process of mid wiper lasting and the final pressing.

4. Each set of pincers can be individually adjusted to their corresponding positions and is functioned with automatic balancing. Besides, an automatic down pulling stroke can be selected and controlled according to the tension of the upper.

5. The mid pincers can be adjusted with different angles, which is more feasible for lasting special shape of shoes and can be applied to a wider scope.

6. The wiper is functioned with an inching adjustment system. By means of computer input of necessary lasting points, the setting of wipers' routes becomes easier and faster, and the digital display is clear and legible, which saves the operator much time

7. The last support plate is functioned with an optional 2-step uprising system, which makes the short upper clamping easier. Moreover, with the function of clamping pressure decrease of pincers, the incident of over pulling and breaking uppers can avoided, which saves the loss caused by manual operation, material and labor cost.

8. The hydraulic system is a design of high and low pressure cycle loop, which ensures a steady oil temperature and makes every part a longer life and better steadiness. All pressure adjustment and timers are set on the outside of the machine to have machine operated and adjusted more conveniently.

9. No distance between the forth and sixth pincers, which can be adjusted for the rotation of different angles and make the upper more attached to the last. Moreover by the aid of supplemental wipers the quality of the lasting can be always perfect.

10. The adhesive applicator can be optionally 2-step adjusted to match the shape of shoes and can also be quickly switched for different sizes of shoes, which makes the cementing point bigger and cementing result better.

11. The newly designed adjustment mechanism for last support plate and adhesive applicator's going forwards and backwards can help the last support plate and adhesive applicator easily adjusted to the most appropriate position according to the cementing point of mid insole upper.

12. Two side pincer can be adjusted easily to suitable angle, and change the second pincer position according to toe shape. To save the time when changing last.

13. The height of inner holder is adjusted by outsetted controller, the information is shown for record, make operation process much easier.

Dimension: 1960*1050*2000mm

Output:1500-1800 pairs

Weight: 800kg

Power: 2.2kw

Heating :1750w

Hydraulic: 50kg/cm2

| Packaging Detail:International Standard Wood Packing |

| Delivery Detail:15 days |