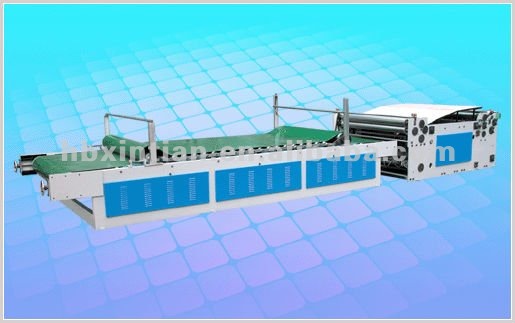

Semi-Automatic carton paper Laminator machine

| Type:Laminating Machine | Condition:New | Application:Machinery & Hardware | Packaging Type:Cartons |

| Packaging Material:Paper | Automatic Grade:Semi-Automatic | Driven Type:Manual | Power:15KW |

| Place of Origin:Hebei China (Mainland) | Brand Name:XinTian | Model Number:TMJ-1300B |

Spec:

Size Knight 1300B

Max Dimensions ofLaminating 1300mm×1100mm

Min Dimensions ofLaminating 350mm×350mm

Machinery Speed 0-90m/min

Power4.5kw

Dimensions of Machine8.0 m×1.98m ×1.26m

Weight5T

Features:

1.Feeding of high table , Automatic feeding for bottom sheet , elastic front register ,simple operator.

2.Just need one person to feeding the paper ,It had low request to paper,suitable for laminating paperboard to bottom paperboard, ABCDE Flute corrugated cardboard, Even filmed paper can be laminated .

3.Top sheet forwarded by manual on high table and the sheet can be piled up to 1.8m .

4.Bottom sheet is automatically feed , the two sheets are piled freely , High efficiency .

5.Advanced elastic front register is used for location , high register precision ,bottom paper will never exceed , When Laminating , it is very easy to make top paper and bottom paper alignment ,or top sheet exceeded.

6.Fully automatic glue supply system : glue will be automatically supplied during lamination , and recovered, avoiding glue wasted.

7.Scientific design for linear speed of metering roller, avoiding glue thrown when high-speed running .

8.The whole machine adopts PLC control system ,compared with other time-delay device or middle relay control, the bottom paper is transferred more precise and stable , furthermore, speed is greatly increase and circuit breakdown can automatically display and alarm.

9.Clean the lower roller in gluing section by blade with circulted water ,complete cleaning, convenient to replace the blade .

- Floating movable pressing section is adopted to make the laminated paperboard smooth , This section can be moved front and back to take in paper conveniently.

- Gear rech is used to control the lift of water tray , which is easily taken out for cleaning .

Working principle:

The sheet first to be transmitted manually to front gauge positioning for orientation , Photo electricity switch starts up the vertical pump valve after receiving the singal and makes the bottom sheet to be absorbed to be belt.

Electromagnetic clutch makes the bottom sheet feed automatically from the feeder

The bottom sheet will be oriented at front positioning together with the sheet after its gluing , then to open the positioning by the thrust which generated from the roller to the bottom sheet .

The top sheet and bottom sheet will be conglutinated through the effect between lamination roller and press roller ,then to be transmitted to the press part .

| Packaging Detail:Wooden box |

| Delivery Detail:20 days |