Scrap Metal Crusher in Metal Recycling Machine for KOBE STEEL(Fortune 500)

| Condition:New | Type:Metal Crushing Machine | Application:scrap metal recycling | Motor Type:DC Motor |

| Power(W):44Kw | Capacity(t/h):3T/h | Place of Origin:Jiangsu China (Mainland) | Brand Name:Dura-Shred |

| Model Number:TM-1347 | Dimension(L*W*H):4092*1416*2163 | Weight:6300kg | Certification:CE&ISO |

| Warranty:Life-long | After-sales Service Provided:Engineers available to service machinery overseas | Motor Specification:Electric-Siemens | Number of Motors:2 |

| HP/KW Range:22Kw | Voltage:as per customer request | Cutting Chamber L*W:1204*686mm | Equipment Weight:24000KG |

| Technologies:America and Japan | Crusher for:Kobe STEEL | Control:Siemens PLC | Output:100mm |

Metal Crusher Description:

1.this machine is low noisy,non-pollution, operation simply, maintain convenient.

2.The can crusher, mainly service for old and useless or discarded materials reuse market .

3.It can crush iron paint kettle, aluminum paint kettle, iron tin can,and paint can into pellets and granular.

4.After crushed into small piece, then it is easy for transportation and also for sake of recycling for reuse purpose.

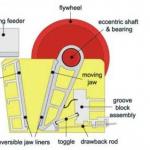

Metal Crusher Features:

1. Geared motor drive.

2. Rugged construction, dense style ribs plate, to ensure that the strong box.

3. Automation button control, safety, convenience.

4. Can be equipped with conveyor belt feed.

Hot selling metal crusher:

are designed with American technologies by our US technical company with an aggressive low RPM, high torque shredding technology. Each shaft is driven by its own Siemens motor, giving it plenty of power to drive through tires and thick steel beads. The shredder blade thickness ranges from 25 mm to 152 mm(1”-6”) depending on the type of metal, throughput, and desired end product.

Shedder machine for metal we designed is energy-saving,low-noise,automatic in normal temperature condition with the best quality guarantee and equipped with best equipment such as Siemens Motor and FAG bearings,controlled by Siemens PLC with SKD-11 steel heated byBodycote.

This shredding machinery system we manufactured forKobe Steellocated in Japan, it is one of Fortune 500 biggest companies of the world,we help to to design this shredding system to shred scrap metal into pieces, then melt again to build new metals.

Equipment specification:

| Metal Crusher | TM2471 | TM1663 | TM1651 | TM1347 | TM1340 | TM1332 | TM832 |

| Motor Spec | 2*Siemens Eletric | 2*Siemens Eletric | 2*Siemens Eletric | 2*Siemens Eletric | 2*Siemens Eletric | 2*Siemens Eletri | 2*Siemens Eletric |

| Power | 55Kw*2 | 45Kw*2 | 37Kw*2 | 22Kw*2 | 22Kw*2 | 15Kw*2 | 7.5Kw*2 |

| Cutting chamber L*W(mm) | 1804*1410 | 1604*858 | 1304*858 | 1204*686 | 1004*686 | 804*686 | 804*460 |

| Equipment Dimensions L*W*H(mm) | 5876*2310 *3493 | 5464*2624 *3040 | 4280*2206 *2492 | 4092*1416 *2163 | 3892*1416 *2163 | 3327*1030 *2075 | 2796*1256 *2311 |

| Equipment Weight | 22400Kg | 13700Kg | 12500Kg | 6300Kg | 5800Kg | 4700Kg | 2000Kg |

| Hopper Opening L*W*H(mm) | 3711*2438 *1046 | 2835*1628 *770 | 2335*1628 *770 | 1521*1416 *685 | 1321*1416 *695 | 1120*1257 *800 | 1120*1256 *800 |

| Product size(mm) | 100-50mm | 100-50mm | 100-50mm | 100-50mm | 100-50mm | 100-50mm | 100-50mm |

We design our equipment to accomplish the following-

- cut storage and disposal costs

- reduce scrap volume up to 80%

- aid in the safe disposal of sensitive, substandard or hazardous materials

We design our crushers based on the following applications

- Tires

- Plastics

- Municipal Solid Waste

- Non-ferrous Materials

- Aluminum

- Paper

- Hazardous Waste

- PCB Capacitors

- Bulky Waste

- Low RAD Waste

- Fiberglass

- Construction/Demolition Debris

- Cloth - Canvas, Rags, Clothing

- Plastic Sheeting, Buckets

- Pallets

- PVC Pipes & Tubes

- Wood

- Document Destruction

Proven Design and Technology.

A quality system with at an affordable price!

Fully Automated via 1 centrally located touch screen control panel.

Backed with one of the best Warrantees in the industry

Metal Shredding System in workshop:

Metal Shredding system in Kobe Steel factory:

Dura-shred's advantage

- Exclusive Control System --- Controls and operates the entire plant from its centrally lacated position and provides instant visibility to what each machine is doing in real time.

- Uniq Stop/ Auto reversal Feature --- Protects against overfeeding and damage by non-processable items.

- Advanced Bearing Housing --- Isolates bearings from cutting chamber contamination and protects agaist bearing failure.

- Premier Full Turnkey Systems --- Plant is manufactured, shipped, installed and ready to start recycling.

- Warranty --- One of the best warrantees in the industry.

If you have any questions, please inquire us freely!

| Packaging Detail:packed according to customer request |

| Delivery Detail:In 30 days after deposit |