SBM Manufacturing Machine,Sand Making Machine Manufacturer

manufacturing machine:, 1 Has ability to control product grading., 2 Low operation cost., 3 Little noise., 4 ISO. - details see: https://www.machineto.com/sbm-manufacturing-machine-sand-making-machine-manufacturer-10318819

| Place of Origin:Shanghai China (Mainland) | Brand Name:SBM | Model Number:PCL Series | Condition:New,Used, Used |

| After-sales Service Provided:Engineers available to service machinery overseas | Year Production:2010 | State production:New | Type:Crusher |

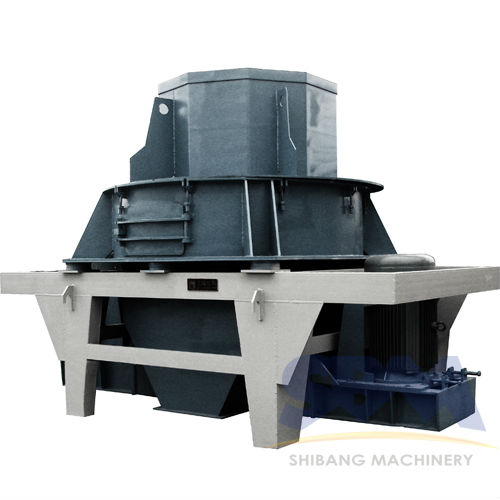

SBM Manufacturing Machine,Sand Making Machine (Manufacturer):

SBM Sand MakingMachine is constructed with an exclusive combination of features thatprovide complete cubical shape of the crushed product, gradationcontrol, and high production yield. For getting cubical crushedproduct, sand making machine should be used as secondary crusher.

Sand making machine is used for artificial sand making purpose. It isused in fine and medium size crushing of coarse material, rocks,stones, minerals, building aggregate concrete and other material.Artificial sand and aggregate is used in preparing good qualityconcrete for building and construction purpose, so the final productmust be cubic with grounded edges. SBM Sand Making Machine isunbeatable in making a consistence cubicle particle shape,

SBM Sand MakingMachine is constructed with an exclusive combination of features thatprovide complete cubical shape of the crushed product, gradationcontrol, and high production yield. For getting cubical crushedproduct, sand making machine should be used as secondary crusher.

Sand making machine is used for artificial sand making purpose. It isused in fine and medium size crushing of coarse material, rocks,stones, minerals, building aggregate concrete and other material.Artificial sand and aggregate is used in preparing good qualityconcrete for building and construction purpose, so the final productmust be cubic with grounded edges. SBM Sand Making Machine isunbeatable in making a consistence cubicle particle shape,

Sand Making Machine Benifits & Technology:

1. Has ability to control product grading.

2. The size of fine products can be adjustable minimum to maximum.

3. High efficiency, low energy consumption.

4. Low operation cost and easy operation.

5. Simple maintenance.

1. Has ability to control product grading.

2. The size of fine products can be adjustable minimum to maximum.

3. High efficiency, low energy consumption.

4. Low operation cost and easy operation.

5. Simple maintenance.

Sand Making Machine Working Principle:

Material from entering hopper into the crushing machine, through thesub-feeder the material is divided into two parts, one part from thesub-feeder middle into the high-speed rotation of the impeller, in theimpeller being rapidly accelerated, and the other part in the form ofstreaming umbrella around the impeller high-speed impact with thecrushed material produced in the whole, under the crushing process, theimpact of broken material with each other on their own, not in directcontact with the metal components, but with material lining the shocksoccur, friction and grinding, which reduces the pollution angle toextend the mechanical wear. Whirl chamber airflow within the cleverself-loop, eliminating the dust pollution.

Material from entering hopper into the crushing machine, through thesub-feeder the material is divided into two parts, one part from thesub-feeder middle into the high-speed rotation of the impeller, in theimpeller being rapidly accelerated, and the other part in the form ofstreaming umbrella around the impeller high-speed impact with thecrushed material produced in the whole, under the crushing process, theimpact of broken material with each other on their own, not in directcontact with the metal components, but with material lining the shocksoccur, friction and grinding, which reduces the pollution angle toextend the mechanical wear. Whirl chamber airflow within the cleverself-loop, eliminating the dust pollution.

PCL Sand Making Machine Specification:

| Model | Max. feeding (mm) | Power(Kw) | Impeller speed (r/min) | Output (t/h) | Outer dimension :L×W×H (mm) | Weight(T) |

| PCL-600 | 30 | 2×30 | 2000-3000 | 12-30 | 3000×1500×2050 | 5.6 |

| PCL-750 | 35 | 2×45 | 1500-2500 | 25-55 | 3300×1800×2440 | 7.3 |

| PCL-900 | 40 | 2×55 | 1200-2000 | 55-100 | 3600×2140×2620 | 12.1 |

| PCL-900B | 40 | 2×75 | 1000-1450 | 65-130 | 3600×2140×2620 | 13.6 |

| PCL-1050 | 45 | 2×(90-110) | 1000-1700 | 100-160 | 4480×2450×3906 | 16.9 |

| PCL-1250 | 45 | 2×(132-180) | 850-1450 | 160-300 | 4520×2640×3100 | 22 |

| PCL-1350 | 50 | 2×(180-220) | 800-1193 | 200-360 | 5340×2940×3650 | 26 |

Note: This specification is just reference, any changes are subject to the products.

| Packaging Detail:exporting standard |

| Delivery Detail:30 days |