sand production line

| Condition:New | Type:Roller Crusher | Application:sand making | Motor Type:AC Motor |

| Power(W):as per models | Capacity(t/h):as per models | Place of Origin:Shandong China (Mainland) | Brand Name:jiuchang |

| Model Number:2PG seris | Dimension(L*W*H):as per models | Weight:as per models | Certification:ISO9001:2008 |

| Warranty:12months | After-sales Service Provided:Engineers available to service machinery overseas |

Sand production line

Introduction of sand production line

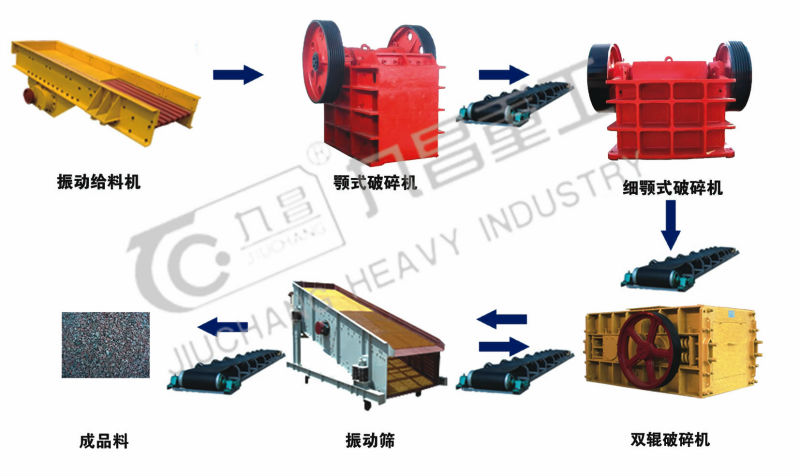

The fine production line which production can be set to 30-200 t/h, is composed of vibrating feeder, jaw crusher, fine jaw crusher, roller crusher, vibrating screen, belt conveyor, electric control system. It is used to crusher solid materials with compressive strength less than 300Mpa such as pebbles, quartz, limestone, granite, basalt for man-made sand making.

The complete sand production line on the basis of working flow is optimizing designed to make different equipments properly matched and strictly spatial crossing arrangement.The configuration of equipments is in accordance with customers’ required models and production capacity. It is equipped with advanced electric control system to make the complete line highly automatization almost without manual operation except start or turn-off and daily maintenance.

It features small occupying area, good sand shape, low powder content and the whole production line runs reliable, convenient operation, high efficient and low power request which is truly the most reasonable and economical production line.

Working principle

Massive materials loaded in the storage bin are evenly sent to jaw crusher by vibrating feeder for coarse crushing. Then primarily crushed materials are transferred to fine jaw crusher by belt conveyor for secondary crushing. The roller crusher will do the fine crushing for the materials coming from fine jaw crusher. The fine crushed materials are turned into vibrating screen for different sizes grading. Qualified sand will be sent to finished products piles by belt conveyor while the unqualified materials are returned to crusher for crushing again. This closed circle flow goes over and over again.

Address:Dongcheng Development Zone,Linqu Weifang,Shandong,PR China

Telephone:0086-536-2082685.

| Packaging Detail:as per models |

| Delivery Detail:45-50dys after deposit paid |