sand making machine from henan/high capacity and low price

| Place of Origin:Henan China (Mainland) | Brand Name:Dongrui | Model Number:diferent model,stone making line | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Certification:ISO, CERT | Dimension(L*W*H)::according to the different models | Warranty:1year |

| colour:as the customers' demand | application:mining stone |

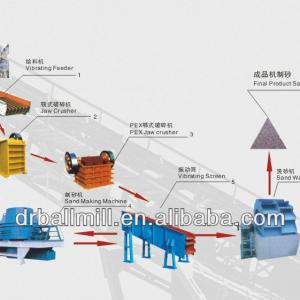

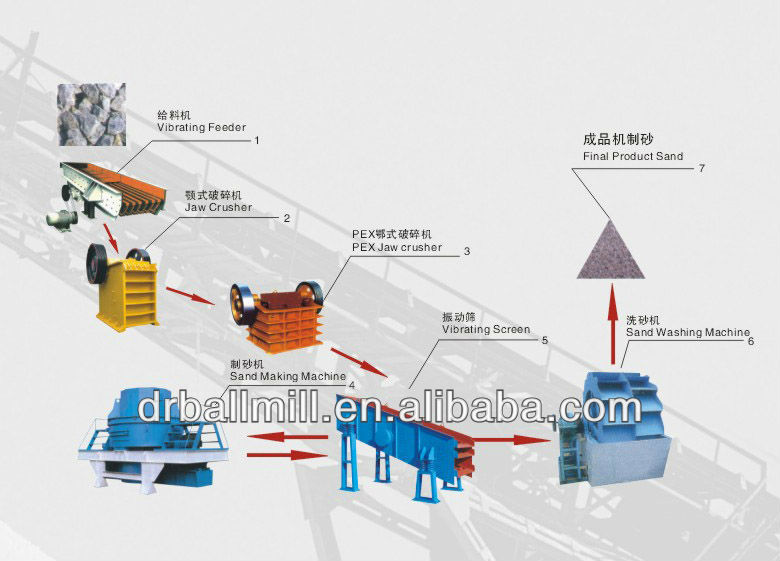

1. Brief introduction of stone production line:

First the raw materials be send to primary crusher(jaw crusher) by vibrating feeder, after first-stage crush, material will be transport to the secondary crusher(impact crusher) by belt conveyor, to get the rather fine size gravel, then these products be separated by vibrating screen to meet the size customer request.

2. Features of the Stone Making Product Line:

The whole line (Stone Crusher Line) is highly automatic and the size of the finished products is even, good-shaped and can be adjustable, with high crushing ratio, low power consumption and high capacity, which is suitable for big, middle and small projects, such as road and bridge construction.

| Capacity production line | Jaw crusher | Impact crusher | vibrating screen |

| 20-30T/H production line | PE400×600(30KW) | PF1007(45KW) | 2YZS1237(5.5KW) |

| 30-50T/H production line | PE400×600(30KW) | PF1010(55KW) | 2YZS1548(15KW) |

| 50-80T/H production line | PE500×750(45KW) | PF1210(90KW) | 3YZS1848(18.5KW) |

| 80-150T/H production line | PE600×900(55KW) | PF1214(132KW,) | 3YZS1860(30KW) |

| 120-200T/H production line | PE750×1060(110KW) | PF1315(160KW,) | 3YZS2160(37KW) |

| 200-300T/H production line | PE750×1060(110KW) | PF1214(132KW) | 3YZS2460(37KW) |

| 300-400T/H production line | PE900×1200(132KW) | PF1315(160KW) | 3YZS2160(37KW) |

Every kind machine of line :

Vibrating feeder:

Product Overview:

During the processing, this machine can transfer the bulk, granular materials to the crushers from the stock bin evenly and continuously in the given time. In the stone and sand production lines, it can feed the crushing equipments continuously and screen the materials coarsely. It is widely used in the crushing and screening equipments of metallurgy, coal, chemical industry, construction material, grinding industry, etc.

Technical parameter:

| Model | Size of Funnel(mm) | Max Feed Size(mm) | Capacity (t/h) | Power (kw) | Overall Dimension L×W×H(mm) |

| GZD-850×3000 | 850×3000 | 400 | 80-120 | 7.5 | 3110×1800×1600 |

| GZD-960×3800 | 960×3800 | 500 | 120-210 | 11 | 3850×1950×1630 |

| GZD-1100×4200 | 1100×4200 | 580 | 200-430 | 15 | 4400×2050×1660 |

| GZD-1100×4900 | 1100×4900 | 580 | 280-500 | 15 | 5200×2050×1700 |

| GZD-1300×4900 | 1300×4900 | 650 | 450-600 | 22 | 5200×2350×1750 |

Jaw crusher :

Product Overview:

Jaw Crusher is most widely used in the international market and has the features of high crushing ratio, even granule, simple structure,easy maintenance, etc. It can be used for fine crushing and coarse crushing. The highest compressive resistance of the crushed materials is 320Mpa. The large and medium-size jaw crushers are the key products of our company. Especially in designing and producing the large-size jaw crusher, we have stood in the front line of our country.

Jaw Crusher Technical Parameters

Model | Feed Opening | Max. Feed Size | Capacity | Power | Discharge Opening | Overall Dimension |

PE-150x250 | 150x250 | 125 | 1-5 | 5.5 | 10-40 | 758x758x794 |

PE-250x400 | 250x400 | 210 | 5-20 | 15 | 20-60 | 1500x1400x900 |

PE-400x600 | 400x600 | 340 | 16-65 | 30 | 40-100 | 1700x1800x1600 |

PE-500x750 | 500x750 | 425 | 50-100 | 55 | 50-100 | 1890x1940x1870 |

PE-600x900 | 600 x 900 | 500 | 50-120 | 55 | 65-160 | 2395x1843x2230 |

PE-750 x1060 | 750 x 1060 | 630 | 52-180 | 110 | 80-140 | 2775x2426x2840 |

PE-800x1060 | 800 x 1060 | 640 | 136-230 | 110 | 100-200 | 2500x2472x2810 |

PE-900x1200 | 900 x 1200 | 750 | 140-260 | 110 | 95-165 | 3400x3200x3500 |

PE-1000x1200 | 1000 x 1200 | 850 | 315-342 | 110 | 195-265 | 3335x3182x3430 |

PE-1200x1500 | 1200×1500 | 1020 | 400-800 | 160 | 150-300 | 4200x3732x4620 |

PEX-250x750 | 250×750 | 210 | 15-30 | 22 | 15-70 | 1400x1300x1350 |

PEX-250x1000 | 250×1000 | 210 | 16-52 | 30 | 25-60 | 1600x2000x1500 |

PEX-250 x1200 | 250×1200 | 210 | 20-60 | 37 | 25-60 | 1900x2200x1500 |

PEX-300 x1300 | 300×1300 | 260 | 30-70 | 55 | 30-90 | 1800x2300x1700 |

Impact crusher:

This kind of machine can crush the large,medium and small size materials(granite, limestone, concrete ,etc)with max feed size less than 500mm and compression strength less than 350Mpa. It is widely used for crushing ore in mining, highway, railway, construction, etc. Presently, by practices, its comprehensive function is superior to the cone crusher.

| Model | Specification(mm) | Feed Opening | Max Feed Size(mm) | Capacity (t/h) | Power (kw) |

| PF-1007 | 1000×700 | 400×730 | 250 | 15-60 | 45 |

| PF-1010 | 1000×1050 | 400×1080 | 300 | 50-90 | 55 |

| PF-1210 | 1250×1050 | 400×1080 | 300 | 70-130 | 90 |

| PF-1214 | 1250×1400 | 400×1430 | 300 | 90-180 | 132 |

| PF-1315 | 1320×1500 | 860×1520 | 350 | 120-250 | 160 |

| PF-1320 | 1320×2000 | 860×2030 | 500 | 160-350 | 200 |

vibrating screen:

Product Overview:

Circular Vibrating Screen is of multilayer and high efficiency. The eccentric shaft vibration exciter and partial block help to adjust amplitude. This kind of screen has long stream line, many specifications and clear screening for different specifications.It has features of credible structure, strong exciting force, high screening efficiency, low noise, convenient maintenance, safe operation, etc. So it is widely used in the quarry, building material, transportation, energy, chemistry, etc.

Model | Screen Mesh (mm) | Layers | Sieve Pore Size(mm) | Max.Feed Size(mm) | Capacity (t/h) | Power (kw) | Vibrating Frequency (r/min) | Double Amplitude (mm) | |

2YZS1237 | 1200×3700 | 2 | 4-50 | 200 | 30-100 | 5.5 | 960 | 4-8 | |

3YZS1237 | 1200×3700 | 3 | 4-50 | 200 | 30-100 | 7.5 | 960 | 4-8 | |

2YZS1548 | 4800×1500 | 2 | 3-100 | 400 | 30-275 | 15 | 870 | 5-9 | |

3YZS1548 | 4800×1500 | 3 | 3-100 | 400 | 30-275 | 15 | 870 | 5-9 | |

2YZS1848 | 4800×1500 | 2 | 3-100 | 400 | 56-330 | 18.5 | 870 | 5-9 | |

3YZS1848 | 4800×1800 | 3 | 3-100 | 400 | 56-330 | 18.5 | 870 | 5-9 | |

2YZS1860 | 6000×1800 | 2 | 3-100 | 400 | 65-586 | 22 | 870 | 5-9 | |

3YZS1860 | 6000×1800 | 3 | 3-100 | 400 | 65-586 | 22-30 | 870 | 5-9 | |

2YZS2160 | 6000×2100 | 2 | 3-100 | 400 | 81-720 | 30 | 730 | 5-9 | |

3YZS2160 | 6000×2100 | 3 | 3-100 | 400 | 81-720 | 30-37 | 730 | 5-9 | |

2YZS2460 | 6000×2400 | 2 | 3-150 | 400 | 100-810 | 37 | 770 | 5-9 |

sand making machine :

The entire center feeding: Material falls into the feed hopper, then enters the high-speed rotary sling wheel from center feeding hole, which is speeded immediately in the sling wheel. The speed can reach several dozens times of the gravity acceleration. Then it is thrown from the sling wheel. First, it is crushed with other rebounded material fell freely from the sling wheel. Then both of them are impacted to the material lining (rock-rock) or strike back block (rock-iron), rebounded and stroke to the top of eddy cavity in the inclined-up direction. Then it moves along deflection-down, and forms a continuous material curtain with the material from the impellers passage. Just like this, the material is stroke, rubbed, crushed twice or more, then is discharged from the down discharging hole.

more picture:

| Packaging Detail:standard container |

| Delivery Detail:30days after payment |