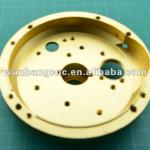

Roller aluminum spacers

1) Roller aluminum spacers, 2) Good surface finish, 3) With high precision, 4) ISO 9001 approved, 5) Over 10 years experience - details see: https://www.machineto.com/roller-aluminum-spacers-10160214

| Place of Origin:Zhejiang China (Mainland) | Brand Name:OEM | Model Number:OEM | Type:Machining Parts |

| Material:Aluminum | Plating:Zinc | Certification:ISO9001:2008 | metal:wahser and spacer |

Roller aluminum spacers

| 1.Name | Roller aluminum spacers |

| 2.Material | Aluminum,Carbon steel; Stainless steel, aluminum alloy; Brass alloy; Tinplate, copper; |

| 3.Machining processes | Metal fabrication, machining, welding, forming, shaping, punching, etc. |

| 4.Surface treatment: | Polishing, zinc plating, nickel plating, chrome plating, powder coating, e-coating, dip coating, phosphate coating, anodize, PVC powder coating, dichromate plating, decrement plating, etc. |

| 5.Machinery and equipments | CNC machining center; General planning and grinding machine;General punching machine, CNC turning center; Wire EDM, 4 or 5 axis-CNC center processes. |

| 6.QC | 1) Technicians self-check in production 2) Engineer spot check in production 3) QC inspects after mass production finished 4) International sales who were trained the technical know-how spot check before shipping |

| 7.Packing | Boxes, Carton, Pallet or as per customer's requirement |

Advantage:

| 1 | More than 10 years experience for serving satisfied customers in North America,Europe,Australia,Southeast Asia and Middle East. |

| 2 | OEM service and Design service are available Min order and sample order is acceptable. |

| 3 | Reply to your inquiries in 24 hours. Your detail requirements will be responded within 24 hours. Your needs will always be treated as our top priority. |

| 4 | Quality control with professional experienced QC team With IS09001:2000 certificate |

| 5 | Delivery the high quality goods on time. |

Material Carbon steel; Stainless steel, aluminum alloy; Brass alloy; Tinplate, copper; Stannum bronze; Silicon bronze; Zinc alloy; Gray iron; Ductile iron; Malleable iron; Tungsten steel, etc. Machining processes Metal fabrication, machining, welding, forming, shaping, punching,

drilling, turning, milling, grinding, chip formatting, rolling,

stamping, deep drawing, bending, spot or seam welding, spinning,

forging, sand casting, die casting,investment casting, etc. Surface treatment: Polishing, zinc plating, nickel plating, chrome plating, powder coating,

e-coating, dip coating, phosphate coating, anodize, PVC powder coating,

dichromate plating, decrement plating, etc. Machinery and equipments: CNC machining center; CNC lathe; Normal lathe; CNC milling machine;

General milling machine; General drilling machine; General planning

and grinding machine;General punching machine, CNC turning center; Wire EDM, etc. And we also

can offer 4 or 5 axis-CNC center processes. Testing machine

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. QC 1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished

4) International sales who were trained the technical know-how spot check before shipping Packing Boxes, Carton, Pallet or as per customer's requirement

drilling, turning, milling, grinding, chip formatting, rolling,

stamping, deep drawing, bending, spot or seam welding, spinning,

forging, sand casting, die casting,investment casting, etc. Surface treatment: Polishing, zinc plating, nickel plating, chrome plating, powder coating,

e-coating, dip coating, phosphate coating, anodize, PVC powder coating,

dichromate plating, decrement plating, etc. Machinery and equipments: CNC machining center; CNC lathe; Normal lathe; CNC milling machine;

General milling machine; General drilling machine; General planning

and grinding machine;General punching machine, CNC turning center; Wire EDM, etc. And we also

can offer 4 or 5 axis-CNC center processes. Testing machine

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. QC 1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished

4) International sales who were trained the technical know-how spot check before shipping Packing Boxes, Carton, Pallet or as per customer's requirement

| Packaging Detail:Wooden Packing, Carton Packing; Packing per customer's requirements. |

| Delivery Detail:1 month |