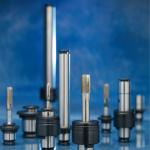

Quick Change Chucks

| Place of Origin:Delhi India | Brand Name:MTC | Model Number:1001 |

QUICK CHANGE CHUCK -MODEL NO. 1001

Available in sizes : MT – 2, 3, 4, 5 & 6

Made from case hardening steel 16MnCr5 (Equivalent to SAE 8620) and hardened to 55 - 60 HRc approx.

APPLICATION : In continuous flowing productions where one operation is carried out after the other in sequence like drilling, reaming, tapping, counterboring, camfering etc. Primarily used on Radial Drilling machines. Can also be used on ordinary Drilling machines, Tapping machines, Milling machines, Capstan and Turret Lathes etc.

ADVANTAGE : The conventional method of tool change is to use drill drifts / ejectors. There is ample loss of time by this method since the machine has to be stopped, the tool to be removed and the next tool to be mounted. However using the quick change chuck it is a matter of seconds before the tool is changed. The machine is not even required to be

stopped.

COLLETS & FLOATTING HOLDERS FOR

Quick Change Chuck

Available in sizes | ||

CO-21, 22 | (Suitable for QCC MT-2) | |

| CO-31, 32, 33 | (Suitable for QCC MT-3) | |

| CO-41, 42, 43, 44 | (Suitable for QCC MT-4) | |

| CO-51, 52, 53, 54, 55 | (Suitable for QCC MT-5) | |

| CO-62, 63, 64, 65 | (Suitable for QCC MT-6) | |

Similar Sizes also available for Floating Reamer Holders (FR) | ||

Made from case hardening steel 16MnCr5(Equivalent to SAE 8620)and hardened to 55-60 HRc approx. | ||

CO are used for drilling operations whereas FR for reaming. | ||

| Nomenclature : eg. CO - 32 3 - Suitable for QCC MT- 3, 2 - Internal Taper MT - 2. | ||

| Packaging Detail:AS PER STANDARD |

| Delivery Detail:3 WEEKS |