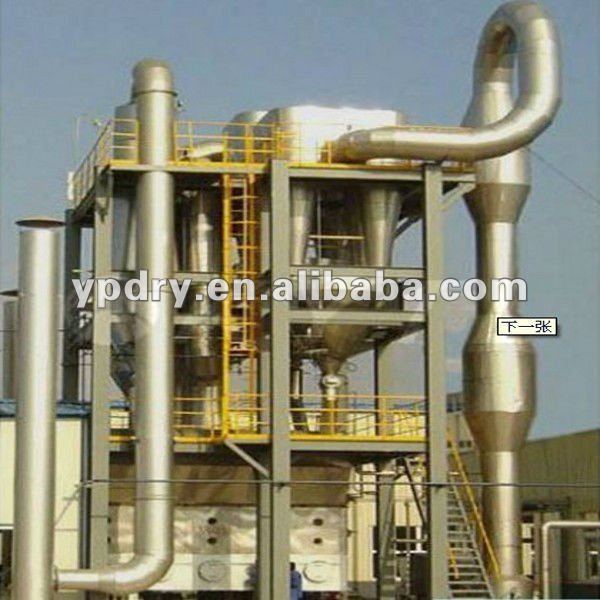

QG Series Pulse Air Stream Drying equipment/air Dryer

| Condition:New | Type:Dehumidifier | Place of Origin:Jiangsu China (Mainland) | Brand Name:yeping |

| Model Number:QG Series Drying equipment | After-sales Service Provided:Engineers available to service machinery overseas | Machine Type:QG | material:stainless steel |

| evaporation:50-1500kg/h | exchange time:200 | steam consumption:120-2500kg | work pressure:0.6-0.8Mpa |

:

Drying equipmentDESCRIPTIONS

QG Drying equipment pulse air stream drying equipment is large bath drier,it adopt instant drying principle,use the hot air which moving fast,drive damp raw material and make it float on the hot air, this strengthen the drying process,improve the speed of heat exchanging,raw material is dried by the drier which non-combine water can remove completely, (for example:raw material's first moisture less than 40%,output of finished product can be 13.5%),raw material doesn't produce metamorphous phenomenon,output increase high than normal drier,the consumer can acquire upper economy benefit in short time.

The drying equipmentequipment is widely used for drying granule and powder raw materials in the field of foodstuff,chemical,pharmacy,construction materials,plastic industry. For example:starch,fish powder,salt,less,gluten,feed,plastic resin,coal powder,A.B.C benzoic acid,2.3 acid,PVC,polypropylene,sodiun sulfate,sodium pyrosulfite and so on. Our company can consultation with the drier,also can design and manufacture non-standard.

QG SERIES PULSE AIR STREAM DRIER drying equipment

FEATURES

QG pulse air steam drying equipment of our company adopts advanced techniques and machines from the United States,has reached the advanced level of the world,the equipment has many advantages listed below; high in automatic degree,little in investment,low in energy consumption,little occupy in area of factory and workpower,wide in applied surface.it is a perfect modern equipment.

drying equipment TECHNICAL PARAMETERS

Name Pa rameter Model | QG-50 | QG-100 | QG-250 | QG-500 | QG-1500 | |

| Evaporation | kg/h | 50 | 100 | 250 | 500 | 1500 |

Air filter | Area(m2) | 4 | 6 | 18 | 36 | 60 |

| unit | 1 | 1 | 1 | 2 | 2 | |

| Exchange time(h) | 200 | 200 | 200 | 200 | 200 | |

Heater | Area(m2) | 30 | 43 | 186 | 365 | 940 |

| Steam consumption(kg) | 120 | 235 | 450 | 972 | 2430 | |

| Work pressure(Mpa) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

Ventilator | Model | 9-19-4. 5 | 9-26-4.5 | 9-19-9 | 9-19-9 | 9-26-6.3 |

| unit | 1 | 1 | 1 | 2 | 4 | |

| Power(kw) | 7.5 | 11 | 18.5 | 37 | 125 | |

Feeder | Amount of transportation(kg/h) | 150 | 290 | 725 | 1740 | 4350 |

| Control way | electromagnetic adjustable speed motor | electromagnetic adjustable speed motor | electromagnetic adjustable speed motor | electromagnetic adjustable speed motor | electromagnetic adjustable speed motor | |

| Power(kw) | 0.75 | 1.1 | 3 | 3 | 7.5 | |

Cyclone separator | Model | CLK-350-400 | CLK-500-450 | ZF12.5 | ZF12.5 | |

| Efficiency | 98 | 98 | 98 | 98 | ||

| Amount | 2 | 2 | 2 | 3 | ||

Bag filter | Amount | 1 | 1 | 1 | 1 | 1 |

| Gas consumption(m3/h) | 3.6-20.0 | |||||

Drying equipment

| Packaging Detail:wooden case.. |

| Delivery Detail:25 days |